972 XE

Medium Wheel Loaders

Overview

The Cat® 972 XE Wheel Loader delivers increased fuel efficiency, premium performance with simple-to-use standard technologies to boost operator efficiencies, and lower maintenance costs. This machine is designed to meet emission standards without interrupting operation. Improved performance, reliability, durability, and versatility result in a machine that is better built to meet your needs.

- Superior Fuel Efficiency

- Achieve Greater Productivity

- Smart Machine for Efficient Operation

- Proven Reliability

- Safety Features

- Reduced Maintenance Time & Costs

- Durability

- Work in Comfort in the All New Cab

- Purpose-built Specialty Configurations

Superior Fuel Efficiency

- Up to 35% better fuel efficiency compared to previous Cat model.

- Deep system integration of the Cat continuously variable transmission, engine, hydraulic, and cooling systems results in significantly increased performance and fuel efficiency.

- Eliminating the torque converter allows the capability to control engine rpm and machine speed independently, resulting in efficient digging, fine control, and easy operation.

Achieve Greater Productivity

- Continuously variable transmission delivers smooth, fast acceleration and speed on grade.

- Machine maneuvering on grade is made easy with speed-hold and anti-rollback.

- Integrated continuously variable transmission provides maximum, steady power at optimal speeds.

- Advanced rimpull control for best loading efficiency in the pile and tire wear reduction.

Smart Machine for Efficient Operation

- Standard Cat technologies to monitor, manage, and enhance your jobsite operations.

– Product Link™ wirelessly connects the machine to the office, giving you access to production and essential health information needed to make timely, fact-based decisions to help you better run your business.

– New Autodig allows the operator to fully automate bucket loading to improve fill factors and loading time.

– Auto Set Tires promotes proper loading technique, significantly reducing tire slip and tire wear.

– Onboard Job Aids and Operator Controls Help to ease operation.

- Optional Cat Advanced Payload with Assist:

Proven Reliability

- Cat C9.3B engine offers high power density with a combination of proven electronics, fuel, and air systems.

- Equipped with automatic Cat regeneration system, Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF), and Diesel Exhaust Fluid (DEF) tank and pump.

- Features an electric fuel priming pump, fuel-water separator, and secondary filtration system.

Safety Features

- Rear-vision camera enhances visibility behind the machine, helping you work safely and confidently.

- Optional multiview (360˚) vision system helps the operator monitor the surroundings of the machine at all times.

- Optional Cat Detect radar technology enhances awareness by monitoring the working environment and alerts operators to hazards.

Reduced Maintenance Time & Costs

- Extended fluid and filter change intervals reduce maintenance costs by up to 25%.*

- Convenient access to hydraulic and electrical service centers for easy and safe servicing.

- Remote Troubleshoot can connect the machine to the dealer service department to help diagnose problems quickly so you can get back to work.

Durability

- Heavy-duty axles designed to handle extreme applications.

- Full-flow hydraulic filtration system with additional kidney-loop filtration improves hydraulic system reliability and component life.

Work in Comfort in the All New Cab

- Next-generation, easily adjustable seat and suspension for improved operator comfort. It comes in two trim levels and can be equipped with a 4-point harness (kit).

- Increased legroom and adjustable seat controls for increased comfort and efficiency.

- Automatic air conditioning system keeps the cab cool as desired.

Purpose-built Specialty Configurations

- Application-specific arrangements direct from the factory for optimized performance and added durability in the toughest applications, including:

Superior Fuel Efficiency

- Up to 35% better fuel efficiency compared to previous Cat model.

- Deep system integration of the Cat continuously variable transmission, engine, hydraulic, and cooling systems results in significantly increased performance and fuel efficiency.

- Eliminating the torque converter allows the capability to control engine rpm and machine speed independently, resulting in efficient digging, fine control, and easy operation.

- Lower rated engine speed reduces component wear and operating noise.

- Power dense engine burns less fuel by providing power and torque when needed.

Achieve Greater Productivity

- Continuously variable transmission delivers smooth, fast acceleration and speed on grade.

- Machine maneuvering on grade is made easy with speed-hold and anti-rollback.

- Integrated continuously variable transmission provides maximum, steady power at optimal speeds.

- Advanced rimpull control for best loading efficiency in the pile and tire wear reduction.

- New Autodig with Auto Set Tires for consistent high bucket fill factors.

- Application Profiles optimize machine settings for different applications at one push of a button.

- Job Aids help operators improve and optimize their operating skills.

- Performance Series Buckets utilize a system-based approach to balance bucket shape against the machine’s linkage, resulting in higher fill factors and better material retention when compared with other buckets of the same rated capacity.

- Automatic engine idle shutdown system significantly reduces idle time, overall operating hours, and fuel consumption.

- Dual ride control accumulator system enables a wide payload range and better ride quality.

- Standard manual front differential provides additional traction when needed. Automatic front and rear locks are available as an option.

- Optional aggregate handler configuration offers higher payload capability for loose aggregate handling.**

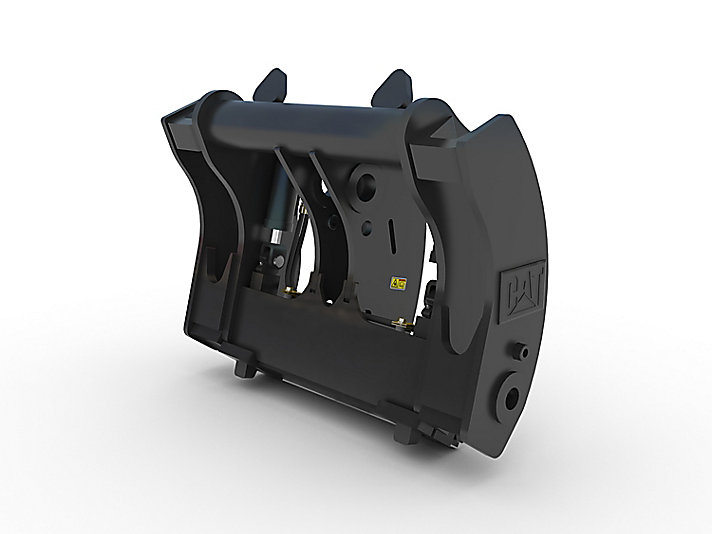

- With Fusion™ Quick Coupler, buckets can be changed without leaving the cab, allowing the machine to quickly move from task to task.

**Optional configurations and equipment may vary from region to region and require conformance to Caterpillar payload policy. Consult your dealer or Caterpillar representative for details.

Smart Machine for Efficient Operation

- Standard Cat technologies to monitor, manage, and enhance your jobsite operations.

– Product Link™ wirelessly connects the machine to the office, giving you access to production and essential health information needed to make timely, fact-based decisions to help you better run your business.

– New Autodig allows the operator to fully automate bucket loading to improve fill factors and loading time.

– Auto Set Tires promotes proper loading technique, significantly reducing tire slip and tire wear.

– Onboard Job Aids and Operator Controls Help to ease operation.

- Optional Cat Advanced Payload with Assist:

– Enhanced lists management, site integration, and extended scale features to help manage and improve productivity and profitability of operations.

- Optional Cat Productivity subscription provides detailed and comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

Proven Reliability

- Cat C9.3B engine offers high power density with a combination of proven electronics, fuel, and air systems.

- Equipped with automatic Cat regeneration system, Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF), and Diesel Exhaust Fluid (DEF) tank and pump.

- Features an electric fuel priming pump, fuel-water separator, and secondary filtration system.

- Thorough component design and machine validation processes result in unmatched reliability and uptime.

Safety Features

- Rear-vision camera enhances visibility behind the machine, helping you work safely and confidently.

- Optional multiview (360˚) vision system helps the operator monitor the surroundings of the machine at all times.

- Optional Cat Detect radar technology enhances awareness by monitoring the working environment and alerts operators to hazards.

- Cab access with wide door, optional remote door opening, and stair-like steps add solid stability.

- Floor-to-ceiling windshield, large mirrors with integrated spot mirrors, and rear-vision camera provide industry leading all-around visibility.

- Computerized monitoring system includes several warning indicators.

- Monitored seat belt is standard and can be enhanced with an optional exterior indicator.

- Optional access light and under-hood service light system to provide illuminated access to the machine and daily checks even in the dark.

Reduced Maintenance Time & Costs

- Extended fluid and filter change intervals reduce maintenance costs by up to 25%.*

- Convenient access to hydraulic and electrical service centers for easy and safe servicing.

- Remote Troubleshoot can connect the machine to the dealer service department to help diagnose problems quickly so you can get back to work.

- Remote Flash works around your schedule to ensure your machine’s software is up to date for optimal performance.

- The Cat App helps you manage fleet location, hours, and maintenance schedules; it also alerts you for required maintenance and allows you to request service from your local Cat dealer.

- Integrated Autolube extends component and service life.

- One-piece tilting hood makes engine compartment access fast and easy.

*Parts and fluids only

Durability

- Heavy-duty axles designed to handle extreme applications.

- Full-flow hydraulic filtration system with additional kidney-loop filtration improves hydraulic system reliability and component life.

Work in Comfort in the All New Cab

- Next-generation, easily adjustable seat and suspension for improved operator comfort. It comes in two trim levels and can be equipped with a 4-point harness (kit).

- Increased legroom and adjustable seat controls for increased comfort and efficiency.

- Automatic air conditioning system keeps the cab cool as desired.

- New in-cab dashboard and high-resolution touch display(s) are easy to use, intuitive, and user friendly.

- Sound suppression, seals, and viscous cab mounts decrease noise and vibration for a quieter work environment.

- The seat-mounted electro-hydraulic joystick steering system provides precision control and dramatically reduces arm fatigue, resulting in excellent comfort and accuracy.

- The next generation of ride control works as a shock absorber, improving ride quality over rough terrain.

Purpose-built Specialty Configurations

- Application-specific arrangements direct from the factory for optimized performance and added durability in the toughest applications, including:

Engine

- Engine Power @ 1,600 rpm - ISO 14396:2002

- 339hp

- Gross Power @ 1,600 rpm - SAE J1995:2014

- 343hp

- Engine Model

- Cat C9.3B

- Net Power @ 1,600 rpm - ISO 9249:2007, SAE J1349:2011

- 316hp

- Note (1)

- Cat engine meets U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 emission standards.

- Note (2)

- The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner, and aftertreatment.

- Net Torque @ 1,200 rpm - ISO 9249:2007, SAE J1349:2011

- 1287ft-lb

- Displacement

- 9.3 L

- Engine Torque @ 1,200 rpm – ISO 14396:2002

- 1375lb/ft

- Note (3)

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: • 20% biodiesel FAME (fatty acid methyl ester)* • 100% renewable diesel, HVO (h

- Gross Torque @ 1,200 rpm – SAE J1995:2014

- 1388lb/ft

Weights

- Operating Weight

- 54858lb

- Note

- Weight based on a machine configuration with Bridgestone 26.5R25 VJTL3 radial tires, full fluids, operator, standard counterweight, ride control,cold start, roading fenders, Product Link, front manual differential/openrear axles, power train guard, second

Transmission

- Forward - 1

- 4.1mile/h

- Forward - 2

- 8.4mile/h

- Forward - 3

- 15mile/h

- Forward - 4

- 24.5mile/h

- Note

- Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 849 mm (33 in) roll radius.

- Reverse - 1

- 4.5mile/h

- Reverse - 2

- 9.2mile/h

- Reverse - 3

- 16.5mile/h

- Reverse - 4

- 24.5mile/h

Sound

- Note (1)

- ** For machines in European Union countries and in countries that adopt the EU Directives.

- Note (2)

- ***European Union Directive 2000/14/EC as amended by 2005/88/EC.

- With Cooling Fan Speed at 70% of Maximum Value - Exterior Sound Power Level*

- 108

- With Cooling Fan Speed at 70% of Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)

- 69dB(A)

- With Cooling Fan Speed at Maximum Speed - Exterior Sound Power Level (ISO 6395:2008)

- 109dB(A)

- With Cooling Fan Speed at Maximum Speed - Exterior Sound Pressure Level (SAE J88:2013)

- 76

- With Cooling Fan Speed at Maximum Speed - Operator Sound Pressure Level (ISO 6396:2008)

- 70dB(A)

- With Cooling Fan Speed at Maximum Value - Note

- Distance of 15 m (49.2 ft), moving forward in second gear ratio.

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.6 kg (3.5 lb) of refrigerant which has a CO2 equivalent 2.288 metric tonnes (2.522 tons).

Operating Specifications

- Breakout Force

- 44072lb

- Note (1)

- For a machine configuration as defined under Weight.

- Note (2)

- Full compliance to ISO 14397-1:2007 Sections 1 thru 6, which requires 2% verification between calculations and testing.

- Static Tipping Load - Full 40° Turn - No Tire Deflection

- 17505kg

- Static Tipping Load - Full 40° Turn - With Tire Deflection

- 35919lb

Service Refill Capacities

- Cooling System

- 17.4gal (US)

- Crankcase

- 6.1gal (US)

- DEF Tank

- 6.9gal (US)

- Differential - Final Drives - Front

- 15.1gal (US)

- Differential - Final Drives - Rear

- 15.1gal (US)

- Fuel Tank

- 80.1gal (US)

- Hydraulic Tank

- 30.1gal (US)

- Transmission

- 15.5gal (US)

Hydraulic System

- Implement System - Maximum Operating Pressure

- 4496psi

- Implement System - Maximum Pump Output at 2,250 rpm

- 99gal/min

- Hydraulic Cycle Time - Total

- 10.7 seconds

Dimensions

- Note

- All dimensions are approximate and based on machine equipped with 5.4 m3 (7.1 yd3) general purpose bucket with BOCE and Bridgestone 29.5R25 VSNT L4 radial tires.

Dimensions - High Lift

- Centerline of Rear Axle to Edge of Counterweight

- 8.1ft

- Centerline of Rear Axle to Hitch

- 5.1ft

- Ground Clearance

- 1.4ft

- Height - Top of Exhaust Pipe

- 11.8ft

- Height - Top of Hood

- 9.5ft

- Height - Top of ROPS

- 11.1ft

- Hinge Pin Height at Carry

- 2.6ft

- Hinge Pin Height at Maximum Lift

- 15.9ft

- Lift Arm Clearance at Maximum Lift

- 13.8ft

- Overall Length - Without Bucket

- 26.6ft

- Tread Width

- 7.3ft

- Wheel Base

- 11.8ft

- Width over Tires (Loaded)

- 9.11ft

- Rack Back at Ground

- 37 degrees

- Rack Back - Maximum Lift

- 71 degrees

- Rack Back - Carry Height

- 49 degrees

Dimensions - Standard Lift

- Centerline of Rear Axle to Hitch

- 5.1ft

- Ground Clearance

- 420mm

- Height - Top of Exhaust Pipe

- 3527mm

- Height - Top of Hood

- 2846mm

- Height - Top of ROPS

- 3589mm

- Hinge Pin Height at Carry

- 2.2ft

- Hinge Pin Height at Maximum Lift

- 4464mm

- Lift Arm Clearance at Maximum Lift

- 3843mm

- Overall Length - Without Bucket

- 7731mm

- Tread Width

- 7.3ft

- Wheel Base

- 3550mm

- Width over Tires (Loaded)

- 9.11ft

- Rack Back - Carry Height

- 49 degrees

- Rack Back at Ground

- 39 degrees

- Centerline of Rear Axle to Edge of Counterweight

- 8ft

- Rack Back - Maximum Lift

- 56 degrees

Bucket Capacities

- Bucket Range

- 2.8-14.0 m³ 3.75-18.25 yd³

Standard/Optional Features

Standard Equipment:

-

- Operator Environment

-

- Cab, pressurized, sound suppression

- Door, remote opening system

- EH implement controls, parking brake

- Steering, joystick

- Seat, suede/cloth, air suspension, heated

- Touchscreen display

- Visibility: mirrors, rear-vision camera

- Mirrors, heated

- Air conditioner, heater, defroster (auto temp, fan)

- Sun visor, front, retractable

- Sun visor, rear, retractable

- Window cleaning platform, front

- Window, front, laminated

-

- On-board Technologies

-

- Cat Payload scale

- Autodig with Auto Set Tires

- Operator ID & machine security

- Application Profiles

- Job Aids

- Controls Help and eOMM

-

- Power Train

-

- Cat C9.3B engine

- Electric fuel priming pump

- Fuel-water separator and secondary fuel filter

- Engine, air precleaner

- Axles, front differential lock

- Axles, ecology drains

- Transmission, continuous variable

- Rimpull control

- Throttle lock mode

- Hill and speed hold on grades

- Service brakes, hydraulic, fully enclosed wet disc, wear indicators

- Park brake, caliper on front axles, spring applied-pressure released

-

- Hydraulics

-

- Implement system, load sensing with electro-hydraulic variable displacement piston pump

- Steering system, load sensing with dedicated variable displacement piston pump

- Ride control, dual accumulators

- Oil sampling valves, Cat XT™ hoses

-

- Electrical

-

- Starting and charging system, 24V

- Starter, electric, heavy duty

- Lights: halogen, 4 work lights, 2 rearvision lights

- Lights: roading with turn signals

-

- Monitoring System

-

- Front dash with analog gauges, LCD display, and warning lights

- Primary touchscreen monitor (Cat Payload, quad screens, machine settings & messages)

-

- Linkage

-

- Standard lift, Z-bar

- Kickouts: lift and tilt

Optional Equipment:

-

- Operator Environment

-

- Entertainment radio (FM, AM, USB, BT)

- Entertainment radio (DAB+)

- CB radio ready

- Seat, leather/cloth, air suspension, heated/cooled

- Multiview (360�) vision system

- Cat Detect rear radar system

- Dedicated rearview screen

- Full cab window guard

-

- On-board Technologies

-

- Cat Advanced Payload

- Cat Payload Printer

-

- Power Train

-

- Turbine, air precleaner

- Radiator, high debris

- Cooling fan, reversible

- Axles, auto differential locks front and rear

- Axles, AOC ready, extreme temperature seals

- Axles, oil cooler

-

- Hydraulics

-

- 3rd and 4th auxiliary functions with ride control

- Quick coupler control

-

- Electrical

-

- Cold start, 120V or 240V

- Lights: LED

- Warning beacon

-

- Monitoring System

-

- Reversing strobe lights

-

- Linkage

-

- High lift, Z-bar

-

- Additional Equipment

-

- Cat Autolube system

- Fenders, roading

- Guards: power train, crankcase, cab, cylinders, rear

- Biodegradable hydraulic oil

- High-speed oil change system

- Toolbox

- Wheel chocks

- Secondary steering system, electrical

-

- Special Configurations

-

- Aggregate handler

- Waste and industrial

- Corrosion resistant