336F L XE Hydraulic Excavator

Excavators

Mini Excavators (20)

-

305.5E2 CR Mini Hydraulic Excavator

-

303.5E2 CR Hydraulic Excavator

-

310 Mini Hydraulic Excavator

-

309 CR Mini Hydraulic Excavator

-

309 CR VAB Mini Hydraulic Excavator

-

308 CR VAB Mini Hydraulic Excavator

-

308 CR Mini Hydraulic Excavator

-

307.5 Mini Hydraulic Excavator

-

306 CR Mini Hydraulic Excavator

-

305 CR Mini Hydraulic Excavator

-

304 Mini Excavator

-

303.5 CR Mini Hydraulic Excavator

-

303 CR Mini Hydraulic Excavator

-

302.7 CR Mini Hydraulic Excavator

-

301.7 CR Mini Hydraulic Excavator

-

301.8 Mini Hydraulic Excavator

-

302 CR Mini Hydraulic Excavator

-

300.9D Mini Hydraulic Excavator

-

300.9D VPS & HPU300 Mini Hydraulic Excavator

-

301.5 Mini Hydraulic Excavator

Small Excavators (6)

-

317 GC Hydraulic Excavator

-

315 Hydraulic Excavator

-

317 Hydraulic Excavator

-

315 GC Hydraulic Excavator

-

313 Hydraulic Excavator

-

313 GC Hydraulic Excavator

Medium Excavators (8)

-

335 Hydraulic Excavator

-

330 Excavator | 30 Ton Excavator / Digger

-

323 Hydraulic Excavator

-

326 Hydraulic Excavator

-

330 GC Excavator | 30 Ton Excavator / Digger

-

325 Hydraulic Excavator

-

320 Hydraulic Excavator

-

320 GC Hydraulic Excavator

Large Excavators (8)

-

336F L XE Hydraulic Excavator

-

349 Hydraulic Excavator

-

Cat® 374 Hydraulic Excavator

-

Cat® 352 Hydraulic Excavator

-

Cat® 395 Hydaulic Excavator

-

Cat® 340 Hydraulic Excavator

-

Cat® 350 Hydraulic Excavator

-

Cat® 336 Hydraulic Excavator

Long Reach Excavation (1)

Demolition Excavators (2)

-

Cat® 352 UHD Ultra High Demolition Hydraulic Excavator

-

340 UHD Ultra High Demolition Hydraulic Excavator

Wheel Excavators (9)

Overview

The 336F L XE is built to keep your production numbers up and your owning and operating costs down while giving you all the power, fuel efficiency, and reliability you need to succeed.

Performance

- Caterpillar XE technology, like the exclusive Cat® Adaptive Control System (ACS) valve enables the machine to consume up to 20% less fuel than the standard 336F L, while delivering the same high level of production.

- The C9.3 ACERT™ engine meets U.S. EPA Tier 4 Final, Korea Tier 4 and EU Stage IV emission standards.

Cat Connect Technology

- Cat Connect technology solutions increase production, minimize operating costs, and optimize return on investment by offering LINK, GRADE, and DETECT technologies.

- Cat Production Measurement brings payload weighting to the cab so you can work more productively and deliver accurate loads with confidence.

Maintenance

- Routine maintenance items like grease points and fluid taps are easy to reach at ground level.

- The side-by-side cooling system enables easy cleaning.

- Multiple S·O·SSM ports and pressure diagnostic taps help prevent maintenance downtime.

Comfort

- The full-size roll-over protective structure (ROPS) certified cab is quiet and comfortable.

- Joystick consoles and armrests are adjustable. Seats are adjustable and feature air suspension and heated and cooled options.

- The LCD monitor is easy to navigate and programmable in 44 languages.

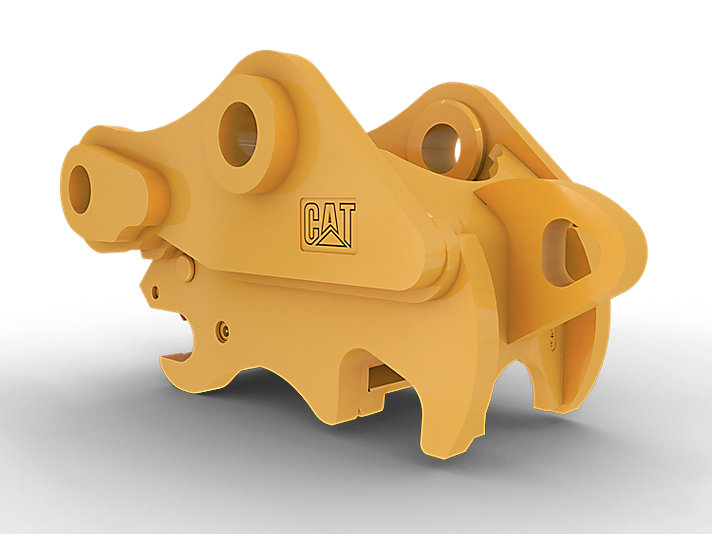

Versatility

- Demolition work is quick and easy with a Cat shear or multiprocessor.

- Quarry work is no problem with a purpose-built Cat bucket and hammer.

- A Cat coupler lets you swap between attachments in seconds without leaving the cab.

- Tool control option remembers pressures and flows for up to 20 tools to enhance uptime.

Durability

- Booms and sticks are built for long service.

- Box-section structures with multi-plate fabrications, castings, and forgings are used in high-stress areas. Track shoes, links, rollers, idlers, and final drives are built with high-tensile-strength steel.

- Greased track link between pins and bushings increases undercarriage life and reduces noise.

Safety

- Smart refuel fills the machine quickly from an external fuel source, it automatically stops when the fuel tank is full or the fuel source is empty, eliminating guess work and premature pump wear.

- The rearview and side-view cameras enhance visibility to help make operators more effective and efficient.

Performance

- Caterpillar XE technology, like the exclusive Cat® Adaptive Control System (ACS) valve enables the machine to consume up to 20% less fuel than the standard 336F L, while delivering the same high level of production.

- The C9.3 ACERT™ engine meets U.S. EPA Tier 4 Final, Korea Tier 4 and EU Stage IV emission standards.

- Automatic engine speed control lowers rpm based on load for reduced fuel consumption.

- Power modes help you more actively manage fuel consumption.

Cat Connect Technology

- Cat Connect technology solutions increase production, minimize operating costs, and optimize return on investment by offering LINK, GRADE, and DETECT technologies.

- Cat Production Measurement brings payload weighting to the cab so you can work more productively and deliver accurate loads with confidence.

- VisionLink® provides wireless access to machine operating data such as location, hours, idle time, fuel usage, productivity, and diagnostic codes to optimize performance.

- Cat Grade Control and AccuGrade™ provide real-time cut and fill information to assist you in attaining grades and slopes more quickly and accurately.

Maintenance

- Routine maintenance items like grease points and fluid taps are easy to reach at ground level.

- The side-by-side cooling system enables easy cleaning.

- Multiple S·O·SSM ports and pressure diagnostic taps help prevent maintenance downtime.

Comfort

- The full-size roll-over protective structure (ROPS) certified cab is quiet and comfortable.

- Joystick consoles and armrests are adjustable. Seats are adjustable and feature air suspension and heated and cooled options.

- The LCD monitor is easy to navigate and programmable in 44 languages.

Versatility

- Demolition work is quick and easy with a Cat shear or multiprocessor.

- Quarry work is no problem with a purpose-built Cat bucket and hammer.

- A Cat coupler lets you swap between attachments in seconds without leaving the cab.

- Tool control option remembers pressures and flows for up to 20 tools to enhance uptime.

Durability

- Booms and sticks are built for long service.

- Box-section structures with multi-plate fabrications, castings, and forgings are used in high-stress areas. Track shoes, links, rollers, idlers, and final drives are built with high-tensile-strength steel.

- Greased track link between pins and bushings increases undercarriage life and reduces noise.

Safety

- Smart refuel fills the machine quickly from an external fuel source, it automatically stops when the fuel tank is full or the fuel source is empty, eliminating guess work and premature pump wear.

- The rearview and side-view cameras enhance visibility to help make operators more effective and efficient.

- Extended hand and guard rails allow for safer climbing to the upper deck, and anti-skid plates reduce slipping hazards in all types of weather conditions.

Service Refill Capacities

- Engine Oil - With Filter

- 8gal (US)

- Hydraulic Tank

- 46gal (US)

- Hydraulic System - Including Tank

- 100gal (US)

- Final Drive - Each

- 2gal (US)

- Swing Drive - Each

- 5gal (US)

- Cooling System

- 11gal (US)

- Fuel Tank Capacity

- 164gal (US)

- DEF Tank

- 11gal (US)

Hydraulic System

- Pilot System - Maximum Flow

- 8gal/min

- Maximum Pressure - Swing

- 4061psi

- Main System - Maximum Flow - Total

- 151gal/min

- Maximum Pressure - Equipment - Heavy Lift

- 5511psi

- Maximum Pressure - Travel

- 5076psi

- Swing System - Maximum Flow

- 74gal/min

- Pilot System - Maximum Pressure

- 595psi

- Maximum Pressure - Equipment - Normal

- 5076psi

Dimensions - HD Reach Boom - 6.50 m (21'4)

- Shipping Length

- 36.61ft

- Track Length

- 16.5ft

- Length - Center of Rollers

- 13.25ft

- Tail Swing Radius

- 11.42ft

- Transport Width - 800 mm (32 in) Shoes

- 11.08ft

- Transport Width - 600 mm (24 in) Shoes

- 10.5ft

- Ground Clearance - Without Shoe Lug Height

- 1.58ft

- Transport Width - 850 mm (33 in) Shoes

- 11.25ft

- Shipping Height - With Shoe Lug Height

- 11.48ft

- Ground Clearance - With Shoe Lug Height

- 1.67ft

- Cab Height - With Top Guard

- 11ft

- Transport Width - 700 mm (28 in) Shoes

- 10.83ft

- Track Gauge

- 8.5ft

- Cab Height

- 10.37ft

- Counterweight Clearance - Without Shoe Lug Height

- 4ft

Machine Weight

- Note (2)

- **336F L XE with 6.1 mt (6.7 t) counterweight, HD reach boom, R3.2DB (10'6") stick, 2.28 m3 (2.98 yd3) GP bucket, 800 mm (32") TG shoes.

- Note (1)

- *336F L XE with 5.1 mt (5.6 t) counterweight, HD reach boom, R3.2DB (10'6") stick, 2.28 m3 (2.98 yd3) GP bucket, 800 mm (32") TG shoes.

- Operating Weight*

- 81800lb

- Operating Weight**

- 85100lb

Drive

- Maximum Drawbar Pull

- 66139lbf

- Maximum Travel Speed

- 3mile/h

Swing

- Swing Speed

- 8.7r/min

Weights

- Operating Weight

- 85100lb

Engine

- Gross Power - SAE J1995

- 238 kW (319 hp/324 PS)

- Net Power - SAE J1349/ISO 9249

- 228 kW (306 hp/310 PS)

- Displacement

- 568in³

- Stroke

- 5.87in

- Bore

- 4.53in

- Net Flywheel Power

- 306hp

- Engine Model

- Cat C9.3 ACERT

- Engine Power - ISO 14396

- 234 kW (314 hp/318 PS)

Working Ranges - HD Reach Boom - 6.5 m (21'4"); R3.2DB (10'6") Stick

- Maximum Depth Cut for 2440 mm (8'0") Level Bottom

- 22.42ft

Sound Performance

- Exterior - ISO 6395

- 105dB(A)

- Operator - SAE J1166/ISO 6396

- 73dB(A)

Working Ranges - HD Reach Boom - 6.5 m (21'4)

- Maximum Digging Depth

- 24.58ft

- Maximum Cutting Height

- 33.83ft

- Maximum Vertical Wall Digging Depth

- 18.08ft

- Minimum Loading Height

- 8.58ft

- Maximum Reach - Ground Level

- 36.17ft

- Maximum Loading Height

- 23.33ft

352 LRE Long Reach Excavation Hydraulic Excavator

352 LRE Long Reach Excavation Hydraulic Excavator  M322F Wheeled Excavator

M322F Wheeled Excavator  M317F Wheeled Excavator

M317F Wheeled Excavator  M320 Wheeled Excavator

M320 Wheeled Excavator  M322

M322  M319 Wheeled Excavator

M319 Wheeled Excavator  M316 Wheeled Excavator

M316 Wheeled Excavator  M318 Wheeled Excavator

M318 Wheeled Excavator  M315 Wheeled Excavator

M315 Wheeled Excavator  M314 Wheeled Excavator

M314 Wheeled Excavator