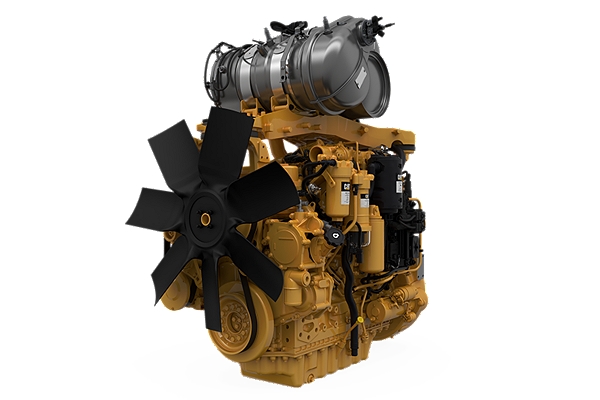

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat® C9 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

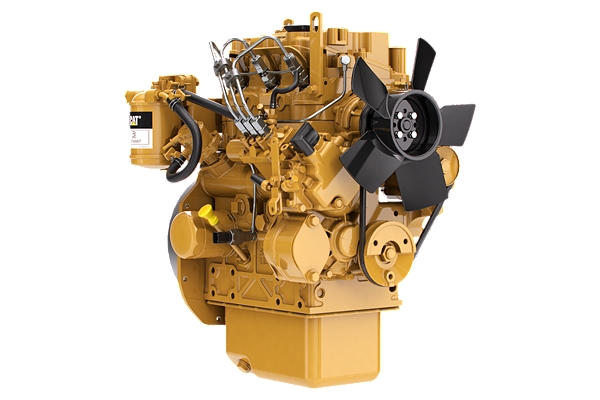

Cat® C2.2 Diesel Engine

-

Cat?� 3512 Fire Pump

-

Cat?� 3406C Fire Pump Engine

-

Cat?� 3508 Fire Pump

-

Cat?� 3516 Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat?� C18 Diesel Fire Pump

-

Cat?� C18 Industrial Power Unit

-

Cat?� C15 Industrial Power Unit

-

Cat?� C13 Industrial Power Unit

-

Cat?� C11 Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit

-

Cat?� C32 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C18 Industrial Power Unit (<560 kW)

-

Cat?� C15 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit HRC

-

Cat?� C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� 3616 Industrial Diesel Engine

-

Cat?� 3612 Industrial Diesel Engine

-

Cat?� 3608 Industrial Diesel Engine

-

Cat?� 3606 Industrial Diesel Engine

-

Cat?� 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat?� 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat?� 3512B Industrial Diesel Engine

-

Cat?� 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat?� 3508 Diesel Engine

-

Cat?� C32

-

Cat?� C27 Industrial Diesel Engine

-

Cat?� C18 Industrial Diesel Engine

-

Cat?� C15 Industrial Diesel Engine

-

Cat?� 3406C Diesel Engine

-

Cat?� C13 Industrial Diesel Engine

-

Cat?� C11 Industrial Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7 Industrial Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?�3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat?� C3.6 Industrial Diesel Engine

-

Cat?� C2.8 Industrial Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C0.7 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat?� 3516E Diesel Engine

-

Cat?� C32 Diesel Engine

-

Cat?� C27 Diesel Engine

-

Cat?� C9.3B Diesel Engine

-

Cat?� C32B HRC Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C3.6 Diesel Engine

-

Cat® C2.8 Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C0.5 Diesel Engine

Overview

Demanding conditions, applications and environments make the Cat?� C7.1 engines the perfect solution for your severe duty equipment. With decades of diesel engine innovation and expertise behind these engines, they deliver the low operating costs and legendary Cat reliability and durability that give you a powerful advantage. More importantly, they’re backed by the world-class Cat dealer network ready to service and support every Cat industrial engine. Industries and applications powered by C7.1 engines include: Agriculture, Ag Tractors, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Combines/Harvesters, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Feller Bunchers, Forestry, Forklifts, General Industrial, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Sweepers, Paving Equipment, Pumps, Skidders, Specialty Ag Equipment, Sprayers, Trenchers and Underground Mining Equipment. Cat?� C7.1 Industrial Diesel Engines, with ratings: 129-225 bkW (172-301.8 bhp) @ 2200 rpm, meet U.S. EPA Tier 4 Final, EU Stage V emission standards. This information about Emissions describes the particular rating’s emissions technology. For more information about emissions certification, please contact your local Cat dealer.

- Installation

- Advanced Features

- Ideal Applications

- Total Cost of Ownership

- Cat Dealer Product Support

- Safety

General

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Cooling System Capacity

- 15.2 L (16 qt)

- Lube System (refill)

- 13-16 L (13.7-16.9 U.S. qts)

- Bore

- 4.1in

- Stroke

- 5.3in

- Displacement

- 427.7in³

- Aspiration

- Turbocharged-Aftercooled (TA) or Series Turbocharged Aftercooled (TTA)

- Compression Ratio

- 16.5:1

- Combustion System

- Direct Injection

- Rotation from Flywheel End

- Counterclockwise

- Engine Configuration

- In-Line 6

- Bore

- 105 mm (4.1 in)

- Stroke

- 135 mm (5.3 in)

- Displacement

- 7 L (427.7 in³)

- Cooling System - Capacity

- 15.2 L (16 qt)

- Lube System - Refill

- 13-16 L (13.7-16.9 U.S. qts)

- Aftertreatment

- DOC+DPF+SCR

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 1063.7 mm (41.9 in)

- Width

- 753-820.2 mm (29.6-32.3 in)

- Height

- 907 mm (35.7 in)

- Weight - Net Dry (Basic Operating Engine Without Optional Attachments)

- 715 kg (1576 lb)

Aftertreatment Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 771-918.7 mm (30.4-36.2 in)

- Width

- 714.4-793 mm (28.1-31.2 in)

- Height

- 468-643.9 mm (18.4-25.3 in)

- Weight

- 90-134 kg (198-295.4 lb)

- Diameter

- 287-337.8 mm (11.3-13.3 in)

Power Rating

- Minimum Power

- 172hp

- Maximum Power

- 320hp

- Rated Speed

- 2200 rpm

- Maximum Torque

- 935lb-ft @ 1400 rpm

Emission Standards

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

Engine Dimensions - Approximate

- Length

- 41.9in

- Height

- 907 mm (35.7 in)

- Length

- 1063.7 mm (41.9 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 715 kg (1576 lb)

- Width

- 753-820.2 mm (29.6-32.3 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 1658lb

- Width

- 31.4in

- Height

- 35.9in

Aftertreatment Dimensions

- Length

- 29in

- Width

- 30.3in

- Height

- 18.1in

- Weight

- 236lb

Aftertreatment Dimensions - Approximate

- Diameter

- 287-337.8 mm (11.3-13.3 in)

- Height

- 453-455 mm (17.8-18.1 in)

- Length

- 610-733 mm (24-28.9 in)

- Weight

- 65-107 kg (143.3-235.9 lb)

- Width

- 623-769 mm (24.5-30.3 in)

Aftertreatment Dimensions*

- Diameter

- 13.3in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet

-

- Standard air cleaners

-

- Control System

-

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

-

- Cooling System

-

- Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

- 50:50 water glycol mix

- Guidance on cooling system design available through your dealer to ensure equipment reliability

-

- Flywheels And Flywheel Housing

-

- Wide choice of drivetrain interfaces, including SAE No. 1, SAE No. 2, and SAE No. 3 configurations

-

- Fuel System

-

- Electronic high pressure common rail

- Innovative filter design to ensure maximum protection of the engine

-

- Lube System

-

- Wide choice of sumps for different applications

-

- General

-

- Paint: Caterpillar yellow, with optional colors available on request

-

- U.s. Epa Tier 4 Final, Eu Stage V, Japan 2014 (tier 4 Final) Aftertreatment/ Clean Emissions Control Equipment

-

- Clean Emissions Module (CEM), consisting of Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC)

- NOx Reduction System (NRS)

- Selective Catalytic Reduction (SCR)

- 3" flex pipe connection with straight, 45°, and 90° options for flexibility

Optional Equipment: