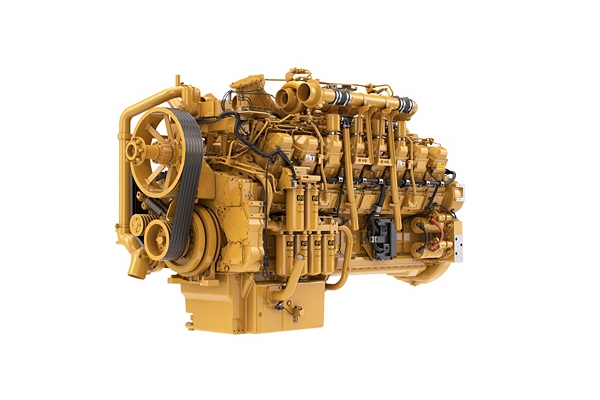

Cat?� 3516C Industrial Diesel Engine

Industrial

Industrial (71)

-

Cat® C9 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

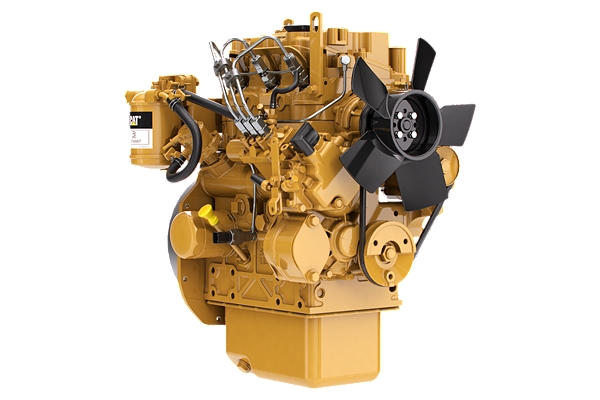

Cat® C2.2 Diesel Engine

-

Cat?� 3512 Fire Pump

-

Cat?� 3406C Fire Pump Engine

-

Cat?� 3508 Fire Pump

-

Cat?� 3516 Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat?� C18 Diesel Fire Pump

-

Cat?� C18 Industrial Power Unit

-

Cat?� C15 Industrial Power Unit

-

Cat?� C13 Industrial Power Unit

-

Cat?� C11 Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit

-

Cat?� C32 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C18 Industrial Power Unit (<560 kW)

-

Cat?� C15 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit HRC

-

Cat?� C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

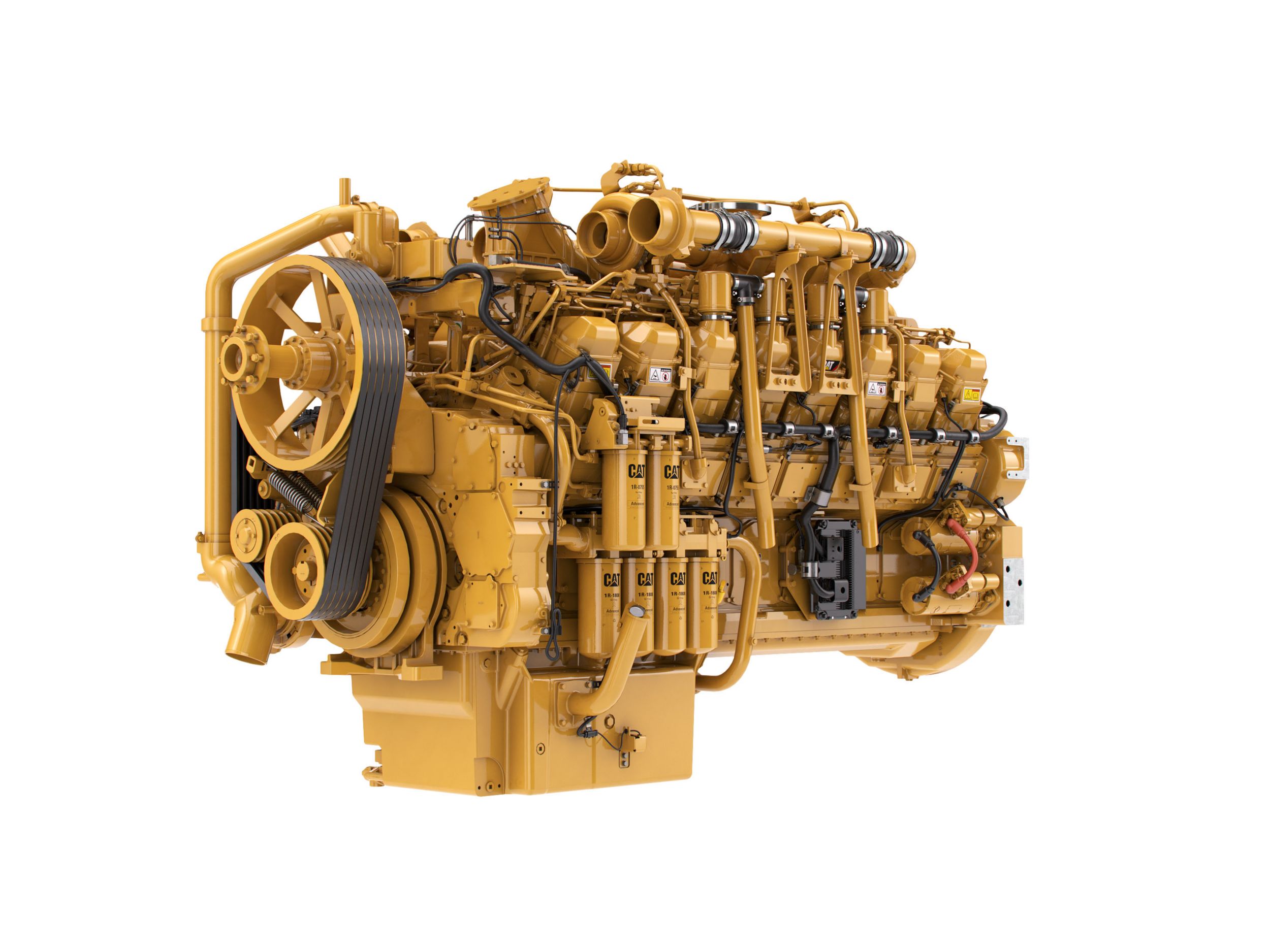

Cat?� 3616 Industrial Diesel Engine

-

Cat?� 3612 Industrial Diesel Engine

-

Cat?� 3608 Industrial Diesel Engine

-

Cat?� 3606 Industrial Diesel Engine

-

Cat?� 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat?� 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat?� 3512B Industrial Diesel Engine

-

Cat?� 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat?� 3508 Diesel Engine

-

Cat?� C32

-

Cat?� C27 Industrial Diesel Engine

-

Cat?� C18 Industrial Diesel Engine

-

Cat?� C15 Industrial Diesel Engine

-

Cat?� 3406C Diesel Engine

-

Cat?� C13 Industrial Diesel Engine

-

Cat?� C11 Industrial Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7 Industrial Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?�3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat?� C3.6 Industrial Diesel Engine

-

Cat?� C2.8 Industrial Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C0.7 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat?� 3516E Diesel Engine

-

Cat?� C32 Diesel Engine

-

Cat?� C27 Diesel Engine

-

Cat?� C9.3B Diesel Engine

-

Cat?� C32B HRC Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C3.6 Diesel Engine

-

Cat® C2.8 Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C0.5 Diesel Engine

Overview

The Cat?� 3516C is offered at 1506 bkW (2100 bhp) @ 1750 rpm. This engine is available using EPA (U.S.) Flex provisions and for other global regulated and non-regulated areas. It offers unsurpassed performance and durability in a multitiude of industries and applications, including Bore and Drill Rigs, Chippers, Grinders, and Shredders, Cranes, Dredgers, Forestry, Material Handling, Mining and Pumps.

- Reliable, Quiet and Durable Power

- Fuel Efficiency

- Quality

- World-class Product Support Offered Through Global Cat Dealer Network

- World-class Product Support Offered Through Global Cat Dealer Network

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Power Rating

- Minimum Power

- 2100bhp

- Maximum Power

- 2100bhp

- Rated Speed

- 1750 rpm

- Minimum Power

- 2100HP

- Maximum Power

- 2100HP

- Rated Speed

- 1750 rpm

- Maximum Torque

- 7563lb-ft @ 1300 rpm

- Maximum Power

- 2100hp

- Maximum Torque

- 7563lb-ft @ 1300 rpm

- Rated Speed

- 1750 rpm

- Minimum Power

- 2100hp

Emission Standards

- Emissions

- U.S. EPA Tier 2 Nonroad Equivalent Emission Standards (Not Currently EPA Certified)

- Emissions

- U.S. EPA Tier 2 Nonroad Equivalent Emission Standards (Not Currently EPA Certified)

- Emissions

- U.S. EPA Tier 2 Nonroad Equivalent Emission Standards (Not Currently EPA Certified)

General

- Engine Configuration

- V-16, 4-Stroke-Cycle Diesel

- Bore

- 170 mm (6.7 in)

- Stroke

- 215 mm (8.5 in)

- Displacement

- 78 L (4760 in³)

- Aspiration

- Turbocharged Aftercooled

- Compression Ratio

- 14.7:1

- Rotation (from flywheel end)

- Counterclockwise

- Lube System (refill)

- 807 L (852 qt)

- Engine Configuration

- V-16, 4-Stroke-Cycle Diesel

- Bore

- 170 mm (6.7 in)

- Stroke

- 215 mm (8.5 in)

- Aspiration

- Turbocharged Aftercooled

- Displacement

- 78 L (4760 in³)

- Compression Ratio

- 14.7:1

- Rotation from Flywheel End

- Counterclockwise

- Lube System - Refill

- 807 L (852 qt)

- Bore

- 6.7in

- Stroke

- 8.5in

- Displacement

- 4760in³

- Aftertreatment

- -

- Engine Configuration

- V-16, 4-Stroke-Cycle Diesel

- Bore

- 6.7in

- Stroke

- 8.5in

- Displacement

- 4760in³

- Compression Ratio

- 14.7:1

- Aspiration

- Turbocharged Aftercooled

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- -

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 3278 mm (129.1 in)

- Width

- 1530 mm (60.2 in)

- Height

- 2062 mm (81.2 in)

- Weight, Net Dry (Basic Operating Engine Without Optional Attachments)

- 7840 kg (17284 lb)

Engine Dimensions - Approximate

- Height

- 2062 mm (81.2 in)

- Length

- 3278 mm (129.1 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 7840 kg (17284 lb)

- Width

- 1530 mm (60.2 in)

- Height

- 81.2in

- Width

- 60.2in

- Length

- 129.1in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 17284lb

- Length

- 129.1in

- Width

- 60.2in

- Height

- 81.2in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 17284lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Air to Air Aftercooled (ATAAC)

- Four turbochargers, center mounted

-

- Control System

-

- ADEM A4 ECM Electronic Engine Control, RH (10 amp DC power required)

-

- Cooling System

-

- Thermostats and housing

- Gear driven centrifugal jacket water pump

- Connections for radiator cooling

-

- Exhaust System

-

- Exhaust manifold, dry

- Four turbochargers with watercooled bearings

- Two exhaust outlets, 203 mm (8 in) round flange

-

- Flywheels And Flywheel Housing

-

- SAE No. 00 flywheel (183 teeth)

- SAE No. 00 flywheel housing

-

- Fuel System

-

- Fuel filter, LH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

-

- Instrumentation

-

- No standard instrument or gauge panel

-

- Lube System

-

- Crankcase breather, top mounted

- Oil cooler

- Oil filler and dipstick, LH

- Oil pump

- Oil filter, LH, spin-on type

- Front sump oil pan, 500-hour change interval

-

- Mounting System

-

- Trunnion front support

-

- Power Take Off

-

- Front housing, two-sided

-

- Protection System

-

- ADEM A4 ECM monitoring system to provide customer programmable engine

- Deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40 pin customer interface connection

-

- Starting System

-

- Dual 24V electric starting motor, LH, unwired

-

- General

-

- Paint: Caterpillar yellow

- Vibration damper

- Lifting eyes

Optional Equipment: