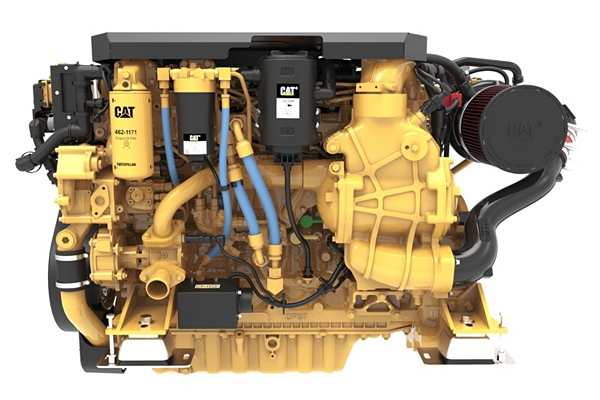

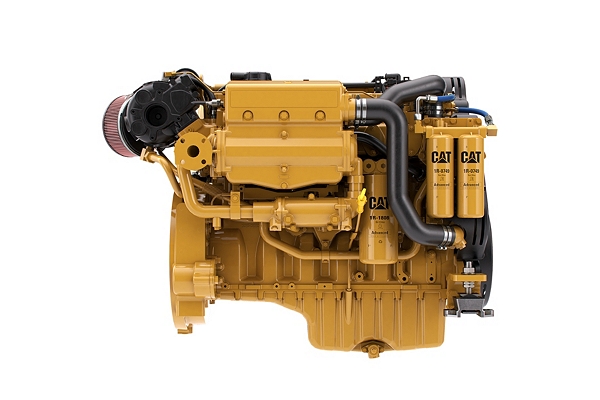

3512E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

Commercial Propulsion Engines

Commercial Propulsion Engines (21)

-

C280-12 Marine Propulsion Engine (EPA Tier 4)

-

C280-8 Marine Propulsion Engine (U.S. EPA Tier 4)

-

C280-12 Propulsion Engine

-

3516C Propulsion Engine (Tier 3)

-

Cat C32 Propulsion Engine (US EPA Tier 4 / IMO III)

-

3508C Propulsion Engine

-

3512C Tier 3 Marine Propulsion Engine

-

Cat C18 ACERT Propulsion Engine (IMO II)

-

Cat C32 Propulsion Engine (IMO II)

-

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

-

C280-16 Commercial Marine Propulsion Engine

-

C280-6 Propulsion Engine

-

Cat C280-8 Propulsion Engine

-

3516E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3512E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3516C

-

Cat C18 ACERT Propulsion Engine (Tier 3)

-

Cat C32 ACERT Marine Propulsion Engine (EPA Tier 3)

-

3512C

-

C7.1 Marine Propulsion Engine (U.S. EPA Tier 3 / IMO II)

-

C9.3 Commercial Propulsion Engine

Overview

The 3512E marine propulsion engine is now available in a wide range of ratings that meet U.S. EPA Tier 4 Final and IMO III marine emissions regulations. As the commercial marine industry adjusts their operations to meet U.S. EPA Tier 4 Final and IMO III emissions standards, Caterpillar Marine has introduced a solution built to maximize performance while meeting regulations. Caterpillar’s combination of a fuel-efficiency-optimized engine and a selective catalytic reduction (SCR) aftertreatment system is a solution that not only reduces NOx emissions, but can also lower a customer’s owning and operating costs in the process.

- Emissions

- Utilizes closed loop air assisted DEF dosing control strategy

- Advanced Engine Combustion Design

- Enhanced control of fuel injection

- Enhanced Fuel Delivery

- Increased Durability and Higher Engine Duty Cycle Capability

- Caterpillar Warranty

- Global Dealer Network

Emissions

Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliant

Utilizes closed loop air assisted DEF dosing control strategy

Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea quality

Advanced Engine Combustion Design

Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiency

Enhanced control of fuel injection

Enhanced control of fuel injection optimized through crank timing and thelatest A5 ECM technology

Enhanced Fuel Delivery

Optimal fuel injector nozzle geometry and electronic injection control for improved fuel delivery

Increased Durability and Higher Engine Duty Cycle Capability

Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capability

Caterpillar Warranty

Industry-leading warranty coverage for factory packaged components

Global Dealer Network

No matter where or when, our extensive global dealer network is ready to provide support.

Emissions

Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliant

Utilizes closed loop air assisted DEF dosing control strategy

Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea quality

Advanced Engine Combustion Design

Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiency

Enhanced control of fuel injection

Enhanced control of fuel injection optimized through crank timing and thelatest A5 ECM technology

Enhanced Fuel Delivery

Optimal fuel injector nozzle geometry and electronic injection control for improved fuel delivery

Increased Durability and Higher Engine Duty Cycle Capability

Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capability

Caterpillar Warranty

Industry-leading warranty coverage for factory packaged components

Global Dealer Network

No matter where or when, our extensive global dealer network is ready to provide support.

Power Rating

- Power Range

- 1341-2549 bhp (1000-1901 bkW)

- Power Range

- 1341-2550 bhp (1000-1902 bkW)

Engine Specifications

- Speed Range

- 1600-1800 rpm

- Emissions

- U.S. EPA Tier 4 Final, IMO III

- Aspiration

- TTA

- Bore

- 6.69in

- Stroke

- 8.46in

- Displacement

- 3574.0in3

- Rotation from Flywheel End

- Clockwise or Counterclockwise

- Configuration

- V 12, 4-Stroke-Cycle Diesel

- Speed Range

- 1600 - 1800 rpm

- Emissions

- U.S. EPA Tier 4, IMO II/III, EU Stage 5

- Aspiration

- Twin Turbocharged - Aftercooled

- Bore

- 6.69in

- Stroke

- 8.46in

- Displacement

- 3574in³

- Approximate Weight

- 12824lb

- Oil Change Interval

- 250 / 500 / 1000

Dimensions & Weights

- Minimum Dry Weight

- 18025.0lb

- Minimum Length

- 104.2in

- Minimum Height

- 91.9in

- Minimum Width

- 71.2in

- Maximum Length

- 125.4in

- Maximum Height

- 92.1in

- Maximum Width

- 81.9in

- Minimum Dry Weight

- 18025lb

- Minimum Length

- 123.5in

- Minimum Height

- 91.9in

- Minimum Width

- 80.2in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Corrosion-resistant aftercooler core

-

- Control System

-

- Dual A5 engine control modules with electronic unit injection and low pressure fuel system

-

- Exhaust System

-

- Dual turbochargers with water-cooled bearings and heat shields

-

- General

-

- Vibration damper and guard

- Meets SOLAS regulations

-

- Fuel System

-

- Duplex Fuel and Oil Filtration

-

- Cooling System

-

- Auxiliary fresh water pump

- Gear Driven, centrifugal jacket water pump with 40% more capacity

Optional Equipment: