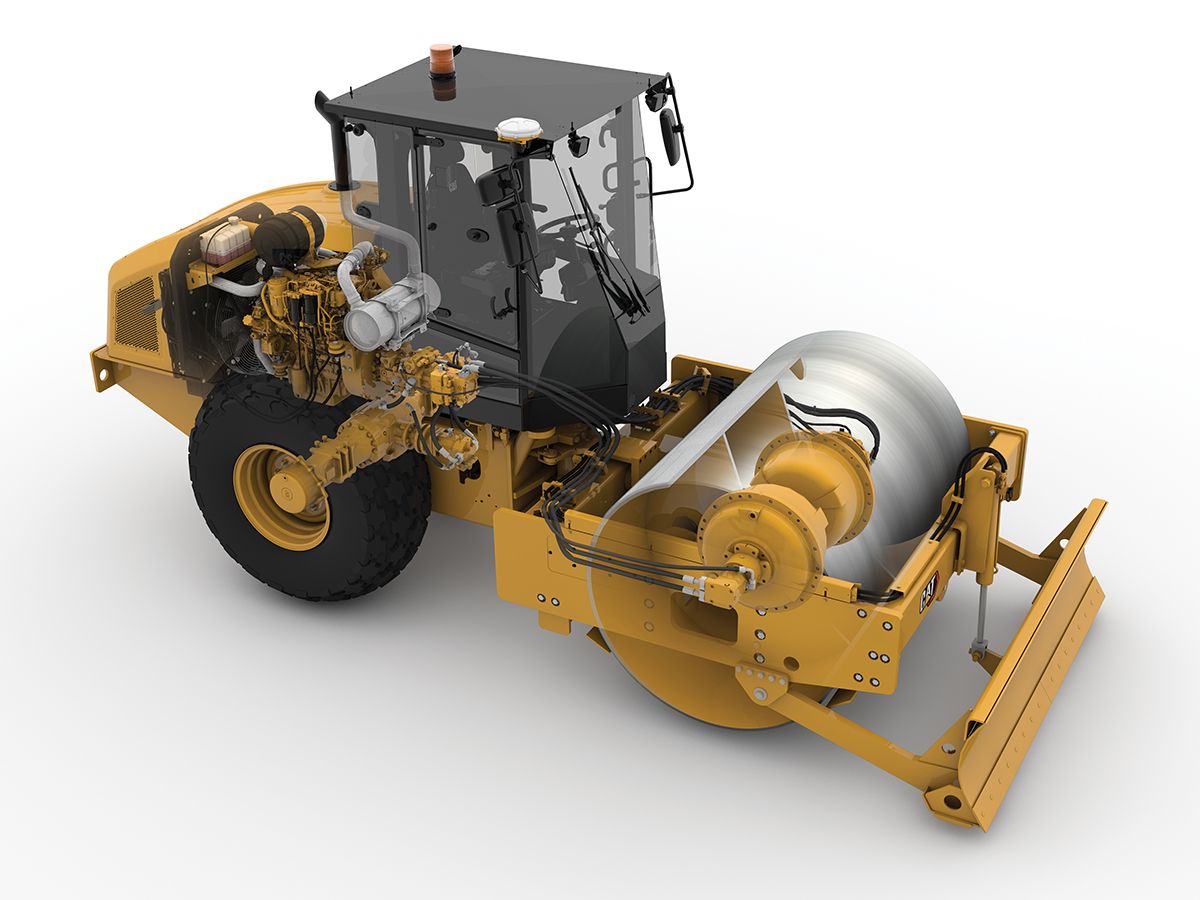

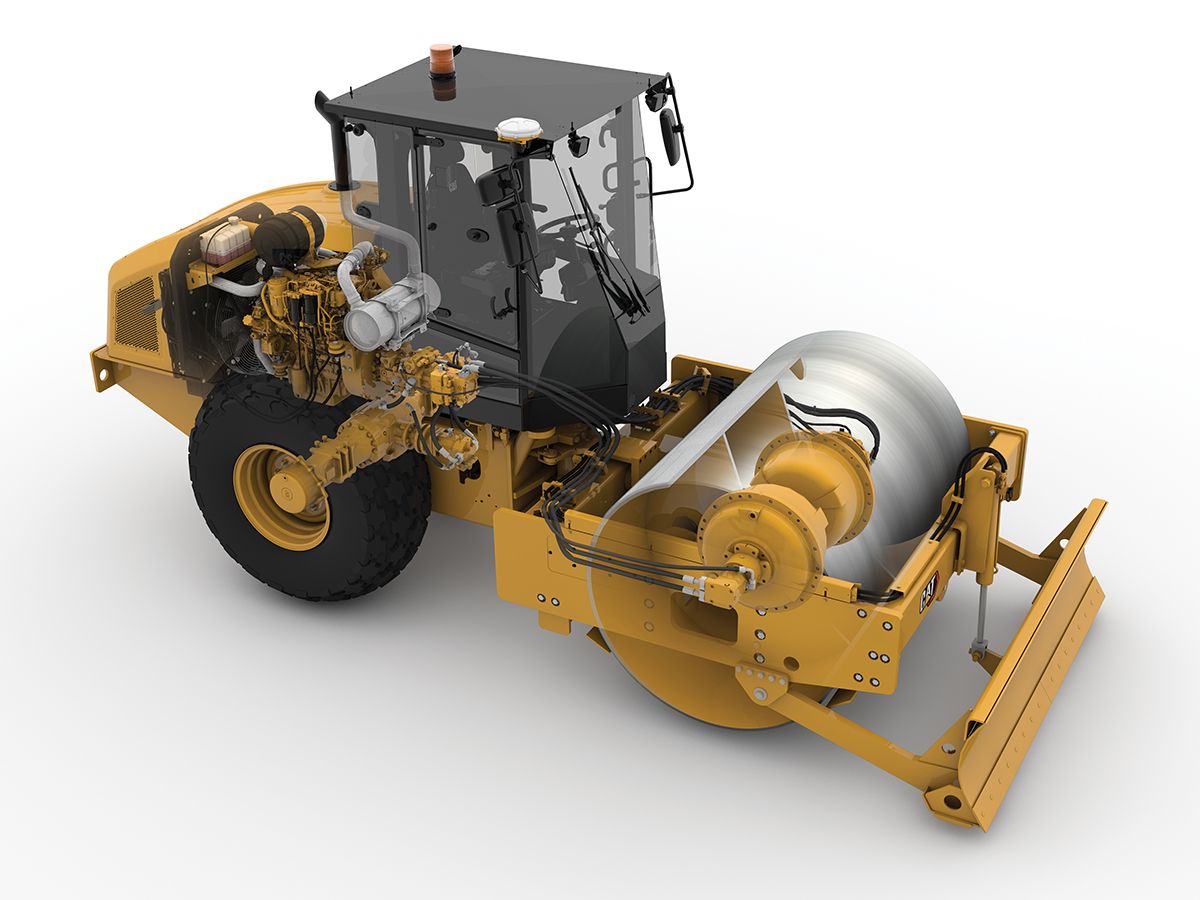

CS11 Vibratory Soil Compactor

Compactors

Landfill Compactors (4)

Pneumatic Rollers (3)

Soil Compactors (2)

Tandem Vibratory Rollers (35)

-

CD54B Drum Steer Tandem Vibratory Roller (Split Drum)

-

CD44B Drum Steer Tandem Vibratory Roller (Solid Drum)

-

CD44B Drum Steer Tandem Vibratory Roller (Split Drum)

-

CD54B Drum Steer Tandem Vibratory Roller (Solid Drum)

-

CB66B Tandem Roller

-

CB64 Vibratory Asphalt Compactors

-

CB54B Tandem Vibratory Roller (Solid Drum)

-

CB54B Tandem Vibratory Roller (Split Drum)

-

CB54 XW Tandem Vibratory Roller

-

CB7 Tandem Roller

-

CB10 Tandem Vibratory Roller

-

CD8 – Solid Drum

-

CD8 – Split Drum

-

CB10 Split Drum Vibratory Roller

-

CCS7 Smooth Drum Vibratory Combination Compactor

-

CD10 Solid Drum Vibratory Roller

-

CC24B Utility Compactor

-

CB24B

-

CCS9 Smooth Drum Combination Vibratory Compactor

-

CB15 Tandem Vibratory Roller

-

CB16 Tandem Vibratory Roller

-

CB10 Tandem Vibratory Roller

-

CB13 Tandem Vibratory Roller

-

CB4.4 Utility Compactor

-

CB7 Tandem Roller

-

CB4.4 Utility Compactor

-

CB4.0 Utility Compactor

-

CC2.7 Utility Compactor

-

CB2.9 Utility Compactor

-

CB2.7 Utility Compactor

-

CB2.5 GC Utility Compactor

-

CB2.7 GC Utility Compactor

-

CB1.8 Utility Compactor

-

CB2.5 Utility Compactor

-

CB1.7 Utility Compactor

Vibratory Soil Compactors (21)

-

CP54B Vibratory Soil Compactor

-

CS54B Vibratory Soil Compactor

-

CP34 Vibratory Soil Compactor

-

CS34 Vibratory Soil Compactor

-

CS56B Vibratory Soil Compactor

-

CP56B Vibratory Soil Compactor

-

CP12 GC Vibratory Soil Compactor

-

CS44B Vibratory Soil Compactor

-

CP44B Vibratory Soil Compactor

-

CS12 GC Vibratory Soil Compactor

-

CS14 Vibratory Soil Compactor

-

CS16 Vibratory Soil Compactor

-

CS19 Vibratory Soil Compactor

-

CS11 Vibratory Soil Compactor

-

CS12 Vibratory Soil Compactor

-

CS13 GC Vibratory Soil Compactor

-

CS11 GC Vibratory Soil Compactor

-

CS10 GC Vibratory Soil Compactor

-

CP11 GC Vibratory Soil Compactor

-

CS5 Vibratory Soil Compactor

-

CS7 Vibratory Soil Compactor

Overview

The Cat® CS11 Vibratory Soil Compactor features a smooth drum and is ideally suited for granular soil applications or cohesive soil applications with the use of an optional padfoot shell kit. A reliable propel system improves performance and efficiency and compaction technology solutions help you reach target density faster.

- Efficient Power

- Exceptional Compaction Performance

- Safe and Comfortable Work Environment

- Enhance Quality and Productivity with Technology

- Virtually Maintenance Free

- Sustainability

Efficient Power

- Built around a dual pump propel system, two pumps provide separate dedicated flow to the drum drive motor and rear axle motor for exceptional gradeability and traction in forward and reverse.

- Powered by a Cat® C4.4 engine that meets U.S. EPA Tier 4 Final emission standards.

Exceptional Compaction Performance

- High static linear loads and amplitudes.

- Exclusive eccentric weight design provides high reliability, smooth performance and low noise.

- Automatic Speed Control and Auto-vibe functions make it easy to ensure consistent, high-quality compaction.

Safe and Comfortable Work Environment

- A rear vision camera with large color touchscreen display enhances visibility for more complete operator control and safety.

- The pivoting seat with integrated multifunction LCD display and control console move with the operator.

- Outstanding visibility to the front and rear of machine.

Enhance Quality and Productivity with Technology

- Optional Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes – saving on fuel and reducing rework and material costs.

- Exclusive Machine Drive Power (MDP) is an energy-based measurement and can be used on all soil types.

Virtually Maintenance Free

- Maintenance-free hitch with sealed-for-life bearings.

- Ground-level access to the engine compartment and cooling module for easy service and fluid sampling.

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 3000 hours eccentric housing and hydraulic oil, and 12000 hours coolant.

Sustainability

- The Cat C4.4 is available in configurations that meet U.S. EPA Tier 4 Final emissions standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details.

*Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Efficient Power

- Built around a dual pump propel system, two pumps provide separate dedicated flow to the drum drive motor and rear axle motor for exceptional gradeability and traction in forward and reverse.

- Powered by a Cat® C4.4 engine that meets U.S. EPA Tier 4 Final emission standards.

- Eco-mode limits engine RPM helping to reduce fuel consumption.

- Engine Idle Shutdown Timer reduces fuel burn and unnecessary idle time by shutting down the machine after a pre-set idling period.

- A variable speed cooling fan operates at the lowest possible speed for optimal cooling.

Exceptional Compaction Performance

- High static linear loads and amplitudes.

- Exclusive eccentric weight design provides high reliability, smooth performance and low noise.

- Automatic Speed Control and Auto-vibe functions make it easy to ensure consistent, high-quality compaction.

- The Variable Frequency option provides a wide range of frequencies to help maximize compaction performance.

- Increase machine versatility with the addition of an oval or square padfoot shell kit, allowing your smooth drum machine to compact semi-cohesive and cohesive materials.

Safe and Comfortable Work Environment

- A rear vision camera with large color touchscreen display enhances visibility for more complete operator control and safety.

- The pivoting seat with integrated multifunction LCD display and control console move with the operator.

- Outstanding visibility to the front and rear of machine.

- Low sound levels and vibration for greater operator comfort and productivity.

- Operators are protected from the elements by a standard equipped ROPS/FOPS canopy or an optional climate-controlled ROPS/FOPS cab with hinged glass windows.

Enhance Quality and Productivity with Technology

- Optional Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes – saving on fuel and reducing rework and material costs.

- Exclusive Machine Drive Power (MDP) is an energy-based measurement and can be used on all soil types.

- Compaction Meter Value (CMV) is an accelerometer-based measurement for granular soils.

Virtually Maintenance Free

- Maintenance-free hitch with sealed-for-life bearings.

- Ground-level access to the engine compartment and cooling module for easy service and fluid sampling.

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 3000 hours eccentric housing and hydraulic oil, and 12000 hours coolant.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- VisionLink® takes the guesswork out of managing your entire fleet–regardless of size or equipment manufacturer*–by providing maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and more through interactive dashboards on your mobile device or desktop, helping you make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API).

Sustainability

- The Cat C4.4 is available in configurations that meet U.S. EPA Tier 4 Final emissions standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details.

*Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. - Auto engine idle shutdown helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- A well-trained operator is worth the investment. Skilled operators benefit your bottom line by maximizing productivity, avoiding costly downtime, and maintaining jobsite safety - which can help to improve fuel efficiency and reduce greenhouse gas emissions.

- Extended maintenance intervals not only reduce downtime but can decrease the amount of fluid and filters that are replaced over the life of the machine. Extend change intervals up to 500 hours engine oil, 3000 hours eccentric housing and hydraulic oil, and 12000 hours coolant.

- Performance and safety can be augmented with standard and optional cameras that are viewed on in-cab displays.

- Cat Compact technologies help you consistently meet compaction targets faster, more uniformly, and in fewer passes - saving on fuel and reducing rework and material costs.

- Cat Scheduled Oil Sampling (S•O•S℠) Services helps reveal excessive wear, contaminated fluids or other "unseen" issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

Engine

- Gross Power

- 132.8hp

- Engine Power - ISO 14396

- 131.3hp

- Net Power - ISO 9249

- 109.8hp

- Net Power - SAE J1349:2011

- 108.4hp

- Note (1)

- Net power advertised is the power available at the engine flywheel when equipped with a fan at maximum speed, air cleaner, clean emissions module, and alternator.

- Engine Model

- Cat® C4.4

- Emissions

- U.S. EPA Tier 4 Final

- Stroke

- 5in

- Bore

- 4.1in

Weights

- Operating Weight - With Cab

- 23823lb

- Operating Weight - With ROPS/FOPS Canopy

- 23380lb

- Weight - Drum with Cab

- 12963lb

- Weight - Drum with ROPS/FOPS Canopy

- 12758lb

- Note (1)

- Operating weights are approximate and consider full fluids and 80 kg (176 lb) operator. Cab weights include heat and air conditioning.

Vibratory System

- Vibratory Frequency - Standard

- 1830VPM

- Variable Frequency Option Range

- 23.3 - 30.5 Hz (1400-1830 vpm)

- Nominal Amplitude - High

- 0.075in

- Nominal Amplitude - Low

- 0.038in

- Centrifugal Force - Maximum

- 54765lb

- Centrifugal Force - Minimum

- 27491lb

- Static Linear Load - With Cab

- 154.3lb/in

- Static Linear Load - With ROPS/FOPS Canopy

- 151.8lb/in

Dimensions

- Compaction Width

- 84in

- Overall Length

- 19.2ft

- Overall Width

- 7.5ft

- Maximum Height

- 10.2ft

- Drum Diameter

- 60.4in

- Wheel Base

- 9.5ft

Operating Specifications

- Ground Clearance

- 17in

- Curb Clearance

- 21.4in

- Turning Radius - Inside Drum Edge

- 12.1ft

- Travel Speed - Maximum

- 6.7mile/h

Service Refill Capacities

- Fuel Tank Capacity

- 69.7gal (US)

- DEF Tank

- 5gal (US)

- Cooling System

- 8.3gal (US)

- Engine Oil - With Filter

- 2.3gal (US)

- Eccentric Weight Housings (combined)

- 6.9gal (US)

- Axle and Final Drives

- 4.8gal (US)

- Hydraulic Tank

- 13.2gal (US)

Sustainability

- Recyclability

- 96%

Standard/Optional Features

Standard Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Operator Environment

-

- ROPS/FOPS Canopy with Handrails, Floor Mat, Vinyl Seat

- Adjustable Seat with Integrated Console

- LCD Display with Lockable Vandalism Guard

- Adjustable Tilting Steering Column with Integrated Cup Holders

- Rear Vision Camera System with Color Touchscreen Display

- High Visibility 50 mm (2 in) Seat Belt

- 12-volt Power Outlet

- Horn, Backup Alarm

-

- Vibratory System

-

- Smooth Drum

- Pod-Style Eccentric Weight Housings

- Dual Amplitude, Single Frequency

- Auto-vibe Function

- Single Adjustable Steel Scraper

-

- Technology Solutions

-

- VisionLink®

-

- Powertrain

-

- Cat® C4.4 Engine

- Air Cleaner, Dual Element

- Three Speed Throttle Switch including Eco-mode

- Automatic Speed Control (ASC)

- Dual Propel Pumps; One for Drum Drive, One for Rear Axle

- Fuel Filter, Water Separator, Priming Pump, Water Indicator

- Tilting Radiator / Hydraulic Oil Cooler

- Dual Braking System

- Two-Speed Hydrostatic Transmission

- Limited Slip Differential

-

- Electrical

-

- 24 volt Electrical System

- 100 ampere Alternator

- 750 Cold-cranking Amps Battery Capacity

-

- Other

-

- Lockable Engine Enclosure, Hydraulic and Fuel Tanks

- Sight Gauges for Hydraulic Oil Level and Radiator Coolant Level

- S·O·S℠ Sampling Values: Engine Oil, Hydraulic Oil, and Coolant

- Halogen Working Lights (4)

Optional Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Operator Environment

-

- ROPS/FOPS Cab with Climate Control, Cloth Seat, Exterior Rear View Mirrors

- Sun Visor (Cab)

- Roll-Down Screen (Cab)

- High Visibility 76 mm (3 in) Seat Belt

-

- Vibratory System

-

- Removable Shell Kit - Oval or Square Pads

- Variable Frequency

- Dual Adjustable Steel Scrapers

- Dual Adjustable Polyurethane Scrapers

-

- Technology Solutions

-

- Measure - Machine Drive Power (MDP)

- Measure - Compaction Meter Value (CMV)

-

- Powertrain

-

- Transmission Guard

-

- Other

-

- Factory Filled Bio-Hydraulic Oil

- Halogen Working Lights (8)

- Amber Rotating Beacon

836K Landfill Compactor

836K Landfill Compactor  826K Landfill Compactor

826K Landfill Compactor  826 Landfill Compactor

826 Landfill Compactor  816 Landfill Compactor

816 Landfill Compactor  CW16 Pneumatic Roller

CW16 Pneumatic Roller  CW34 Pneumatic Roller

CW34 Pneumatic Roller  825K Soil Compactor

825K Soil Compactor  815 Soil Compactor

815 Soil Compactor