275 XE Compact Track Loader

Compact Track Loaders

Overview

The Cat® 275 XE Compact Track Loader, with its vertical lift design, delivers extended reach and lift height for quick and easy truck loading. Its standard equalizer bar (E-bar) undercarriage system and two speed travel provides superior traction, flotation, stability, and speed to work in a wide range of applications and underfoot conditions.

- Redesigned Operator Station

- Available ventilated and heated high-back air ride seat

- High-performance power train

- XE Hydraulic system

- Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine

- Standard equalizer bar (E-bar) undercarriage and standard two-speed travel

- Advanced Touchscreen Monitor

- Advanced Joysticks

- Ground-level access

- Cat Attachments

Redesigned Operator Station

Redesigned Operator Station Larger operating environment and combined with additional seat travel, providing more space for operators of any size.

Available ventilated and heated high-back air ride seat

Available ventilated and heated high-back air ride seat Greater operator comfort.

High-performance power train

High-performance power train Standard two-speed travel, combined with the optional Speed Sensitive Ride Control system for operation on rough terrain, enabling better load retention and increased productivity.

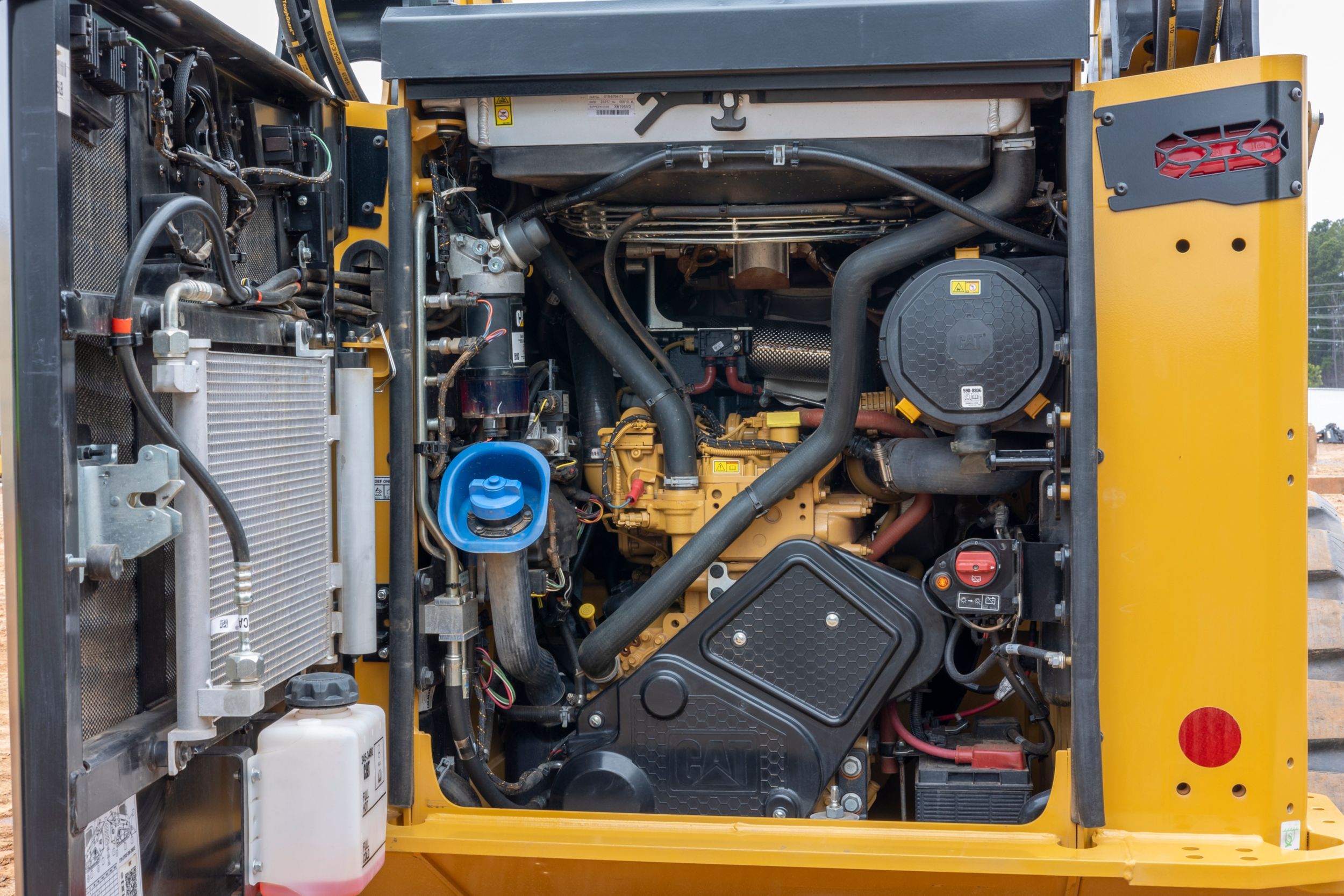

XE Hydraulic system

XE Hydraulic system Highest flow and highest pressure delivering great hydraulic horsepower to efficiently run even the most power-hungry attachments.

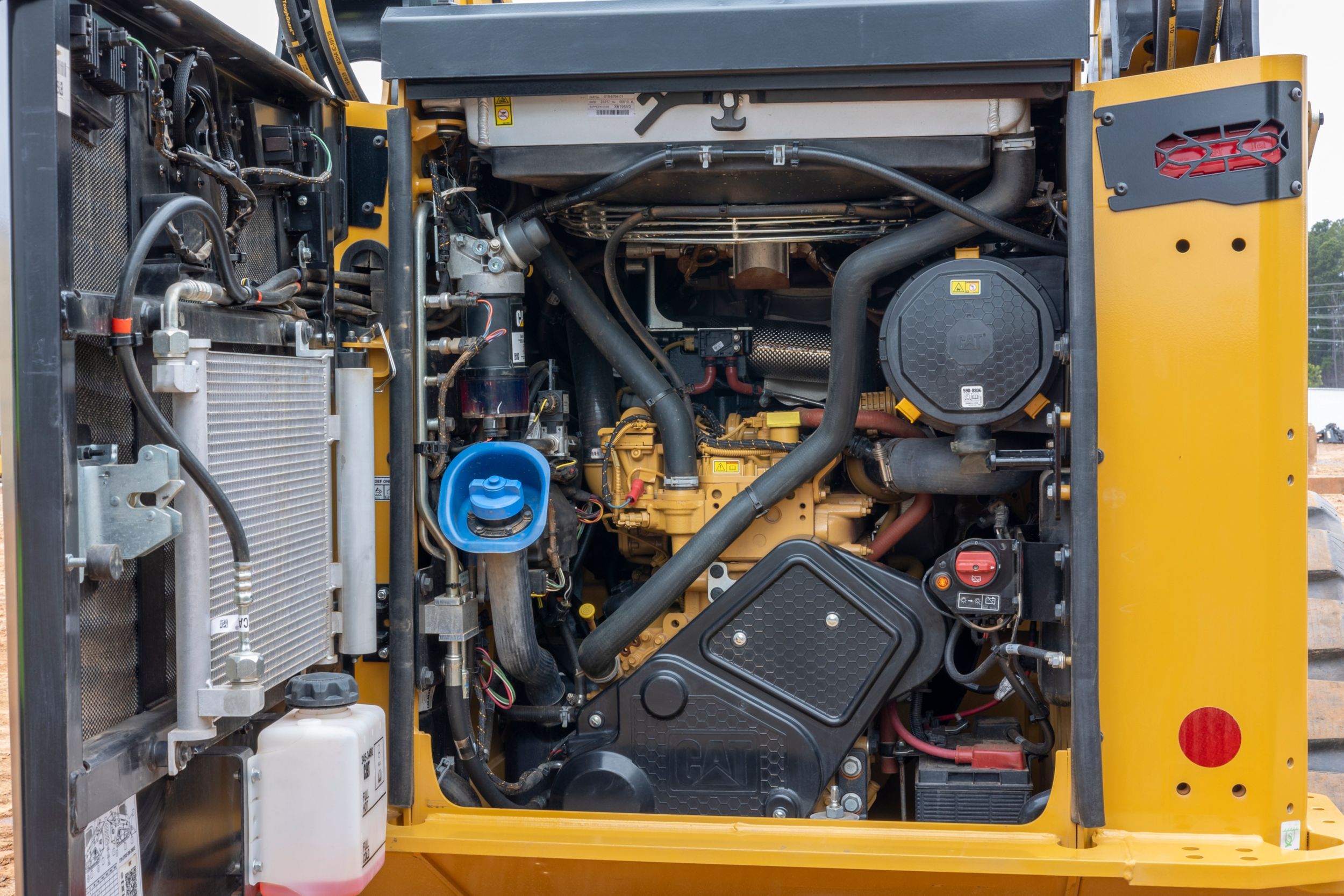

Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine

Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine Maximum horsepower across a wide RPM range and providing high torque for increased working performance, no matter the application.

Standard equalizer bar (E-bar) undercarriage and standard two-speed travel

Standard equalizer bar (E-bar) undercarriage and standard two-speed travel Hybrid undercarriage solution delivers the benefits of a rigid style undercarriage design when lifting heavy loads or when using heavy attachments while also providing the benefits of an oscillating undercarriage design.

Advanced Touchscreen Monitor

Advanced Touchscreen Monitor Offers cutting-edge functionality and control that includes an integrated radio, Bluetooth® connectivity, and multi-camera (side-view) option, and supports 32 different language choices.

Advanced Joysticks

Advanced Joysticks Delivers unmatched control of machine functions and adjustments without operators having to remove their hands from the controls.

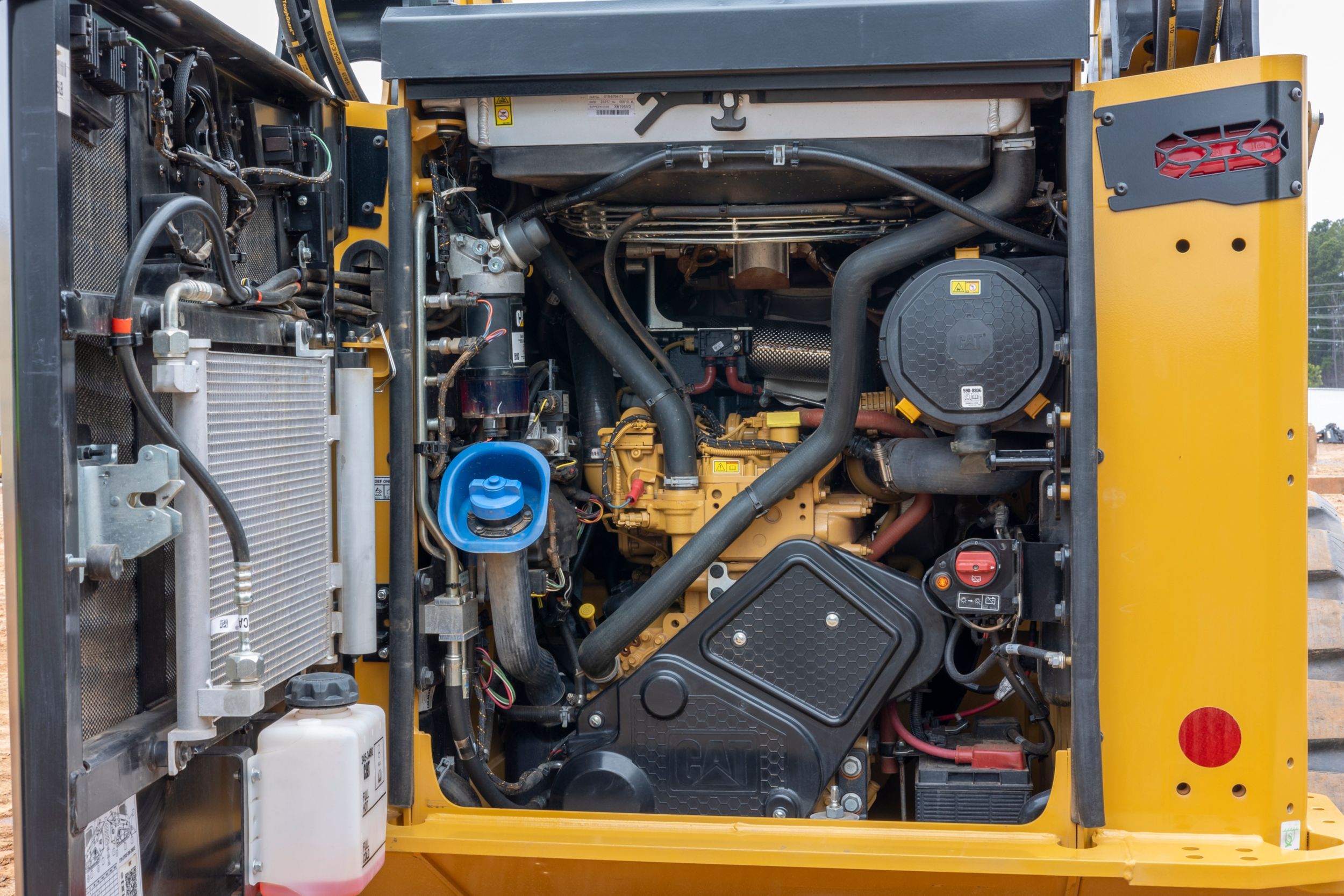

Ground-level access

Ground-level access For all daily service and routine maintenance points help reduce machine downtime for greater productivity.

Cat Attachments

Cat Attachments Make your Cat Compact Track Loader the most versatile machine on the job site.

Redesigned Operator Station

Redesigned Operator Station Larger operating environment and combined with additional seat travel, providing more space for operators of any size.

Available ventilated and heated high-back air ride seat

Available ventilated and heated high-back air ride seat Greater operator comfort.

High-performance power train

High-performance power train Standard two-speed travel, combined with the optional Speed Sensitive Ride Control system for operation on rough terrain, enabling better load retention and increased productivity.

XE Hydraulic system

XE Hydraulic system Highest flow and highest pressure delivering great hydraulic horsepower to efficiently run even the most power-hungry attachments.

Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine

Electronically controlled Cat C3.6TA (turbocharged, aftercooled) engine Maximum horsepower across a wide RPM range and providing high torque for increased working performance, no matter the application.

Standard equalizer bar (E-bar) undercarriage and standard two-speed travel

Standard equalizer bar (E-bar) undercarriage and standard two-speed travel Hybrid undercarriage solution delivers the benefits of a rigid style undercarriage design when lifting heavy loads or when using heavy attachments while also providing the benefits of an oscillating undercarriage design.

Advanced Touchscreen Monitor

Advanced Touchscreen Monitor Offers cutting-edge functionality and control that includes an integrated radio, Bluetooth® connectivity, and multi-camera (side-view) option, and supports 32 different language choices.

Advanced Joysticks

Advanced Joysticks Delivers unmatched control of machine functions and adjustments without operators having to remove their hands from the controls.

Ground-level access

Ground-level access For all daily service and routine maintenance points help reduce machine downtime for greater productivity.

Cat Attachments

Cat Attachments Make your Cat Compact Track Loader the most versatile machine on the job site.

Engine

- Gross Power - SAE J1995

- 122hp

- Bore

- 4.7in

- Displacement

- 221in²

- Net Power - ISO 9249

- 120hp

- Net Power - SAE 1349

- 82hp

- Peak Torque at 1,360 rpm SAE J1995

- 370lb/ft

- Peak Torque - 1,500 rpm - SAE J1995

- 406lb/ft

- Engine Model

- Cat® C3.6 TA (turbocharged after-cooled)

- Stroke

- 3.9in

Hydraulic System

- Hydraulic Flow - XE - Maximum Loader Hydraulic Pressure

- 4496psi

- Hydraulic Flow - High Flow - Loader Hydraulic Flow

- 34gal/min

- Hydraulic Flow - XE - Maximum Loader Hydraulic Flow*

- 40gal/min

- Hydraulic Flow - High Flow - Loader Hydraulic Pressure

- 3500psi

- Hydraulic Flow - XE - Hydraulic Power (calculated)

- 103.9hp

- Hydraulic Flow - High Flow XPS - Hydraulic Power (Calculated)

- 80.7hp

- Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Flow

- 23gal/min

- Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Pressure

- 4061psi

- Hydraulic Flow - Standard - Hydraulic Power (Calculated)

- 46.4hp

- Hydraulic Flow - Standard - Loader Hydraulic Flow

- 23gal/min

- Hydraulic Flow - Standard - Loader Hydraulic Pressure

- 3500psi

Weights*

- Operating Weight

- 12705lb

- Counterweight Adds to Operating Weight

- 428lb

- Counterweight Adds to Operating Weight - ROC (35%)

- 279lb

- Counterweight Adds to Operating Weight - Tip Load

- 796lb

- Enclosed Cab Adds to Operating Weight

- 218lb

- Enclosed Cab Adds to Operating Weight - ROC (35%)

- 105lb

- Enclosed Cab Adds to Operating Weight - Tip Load

- 214lb

- Operating Weight - ROC (35%)

- 4205lb

- Operating Weight - ROC (50%)

- 6008lb

- Operating Weight - Tip Load

- 12015lb

- Note

- * Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, two speed (variable), 2036 mm (80 in) low profile bucket, 400 mm (15.7 in) tracks, triple flange front/rear idler, XE (H6) hydraulics with rear a

Service Refill Capacities

- Cooling System

- 4.6gal (US)

- Engine Crankcase

- 2.4gal (US)

- Fuel Tank

- 36.9gal (US)

- Hydraulic System

- 10.8gal (US)

- Hydraulic Tank

- 6.9gal (US)

- Diesel Exhaust Fluid (DEF) Tank

- 2.9gal (US)

Operating Specifications

- Rated Operating Capacities - 35% Tipping Load

- 4205lb

- Breakout Force - Lift Cylinder

- 6422lb

- Breakout Force - Tilt Cylinder

- 9963lb

- Ground Contact Area - With 450 mm/17.7 in Track

- 2808in²

- Ground Pressure - With 450 mm/17.7 in Track

- 4.5psi

- Rated Operating Capacities - 50% Tipping Load

- 4033lb

- Rated Operating Capacity with Optional Counterweight

- 2996lb

- Tipping Load

- 12015lb

Dimensions

- Bucket Pin Height - Carry Position

- 8.1in

- Bucket Pin Height - Maximum Lift

- 134.4in

- Bucket Pin Reach - Maximum Lift

- 16.3in

- Clearance at Maximum Lift and Dump

- 106.1in

- Departure Angle

- 29.5°

- Ground Clearance

- 11in

- Height - Top of Cab

- 87.8in

- Length - Track on Ground

- 72.3in

- Length - With Bucket on Ground

- 152.8in

- Length - Without Bucket

- 128in

- Maximum Overall Height

- 165.1in

- Maximum Reach - With Arms Parallel to Ground

- 46.1in

- Overall Length - Track

- 92.2in

- Rack Back Angle - Maximum Height

- 86.7°

- Reach at Maximum Lift/Dump

- 32in

- Roll Back Angle

- 27.3°

- Turning Radius from Center - Bucket (racked)

- 91.3in

- Turning Radius from Center - Coupler

- 60.3in

- Turning Radius from Center - Machine Rear

- 76in

- Vehicle Width (450 mm/17.7 in tracks)

- 77.8in

- Maximum Dump Angle

- 44.7°

Cab

- FOPS

- ISO 3449:2005 Level I

- ROPS

- ISO 3471:2008

- FOPS Level II

- ISO 3449:2005 Level II (Optional)

Power Train

- Travel Speed - Forward or Reverse - One Speed

- 5.2mile/h

- Travel Speed - Forward or Reverse - Two Speed

- 7.8mile/h

Dimensions*

- Vehicle Width (400 mm/15.7 in tracks)

- 75.8in

Standard/Optional Features

Standard Equipment:

-

- Standard Equipment

-

- Quick Coupler: Manual or Hydraulic

- High Visibility Seat Belt: 50 mm (2 in), 75 mm (3 in), or 3-point lap/shoulder

- Steel Imbed Rubber Track – 450 mm (17.7 in) bar tread, 450 mm (17.7 in) block tread

- Dual Flange Front Idler/Single Flange Rear Idler or Triple Flange Front/Rear Idlers

-

- Performance Packages

-

- Performance Package HP1: Standard Flow Hydraulics

- Performance Package HP3: High Flow XPS Hydraulics

-

- Comfort Packages

-

- Open canopy: Cup Holder, Cell Phone Pocket, choice of vinyl Seat (Mechanical Suspension, High Back/Heated/Air Ride Seat)

- Enclosed Cab with heat and air conditioning: Side Windows, Cup Holder, Cell Phone Pocket, choice of Seat (Mechanical Suspension, High Back/Heated Air Ride Seat, High Back/Ventilated and Heated Air Ride Seat) and Door choice (Glass or Polycarbonate)

-

- Technology Packages

-

- T2 – Standard Display, Standard Joysticks, traditional Key Start switch, and Rear-view camera.

- T4 – Advanced Touchscreen Monitor, Advanced Joysticks, Push start, X-mount cell phone holder, and a Rear-view camera.

- T5 – T4 + 2 additional side view cameras.

-

- Radio

-

- Radio, none – for open canopy machines and countries not certified for Bluetooth® technology

- Integrated AM/FM radio with Bluetooth technology. Includes USB port, 3.5 mm (0.13 in) AUX input, and BT microphone. Only for use with enclosed cab. Availability varies by country.

- Integrated DAB+/AM/FM radio with Bluetooth technology. Includes USB port, 3.5 mm (0.13 in) AUX input, and BT microphone. Only for use with enclosed cab. Availability varies by country.

-

- Product Link™

-

- Product Link™ Basic series PL243

- Product Link Elite series PLE643

-

- Cooling Fan

-

- On-demand, variable speed hydraulic cooling fan

- On-demand, variable speed hydraulic cooling fan, with automatic and manual purge reversing operation

-

- Guarding And Sealing Packages

-

- HD0 – base guarding and sealing (engine air inlet rain cap, front cab to-frame sealing, and hydraulic fill access door)

- HD1– intermediate guarding and sealing† (HD0 + cab-to-frame side sealing, lockable fuel fill access door, tilt cylinder guarding, and drive line bottom guarding.) †Some equipment varies by region.

- HD2 – most comprehensive guarding and sealing† (HD1 + turbo guard, exhaust stack wrap, DPF wrap, quick disconnect guarding, fully enclosed drive line guarding, under step hydraulic lines guard cover, engine air inlet pre-cleaner.)

-

- Electrical

-

- Work Tool Electrical Harness

- Heavy duty battery

- Battery disconnect with lockout feature

- 12-volt Electrical System

- 85 Ampere Alternator

- LED Work Lights

- Auto Reverse Lights

- Switch Backlighting

- Interior LED Dome Light

- Backup Alarm

- Electrical Outlet, Beacon

- Exterior Courtesy Lighting

- Automatic Work light notification flash when parking brake is released

-

- Operator Environment

-

- Full color LCD monitor: Creep speed control, Drive response adjustment, Implement response adjustment, Drive Power Priority adjustment, Language selection (× 32), Multi-operator Anti-theft Security System and Monitoring, Maintenance schedule and reminders, Event and Diagnostic Code monitoring, Date /Time/Units/Brightness settings, and Smart Technology for use with Smart Attachments.

- Operator Warning System Indicators: Air Filter Restriction, Alternator Output, Armrest Raised/Operator Out of Seat, Engine Coolant Temperature, Engine Oil Pressure, Glow Plug Activation, Hydraulic Supply Filter Restriction, Hydraulic Oil Temperature, Park Brake Engaged, Engine Emission System (where applicable)

- Gauges: Fuel Level, Hour Meter, Hydraulic Temperature, Hour Meter, Battery Voltage, Tachometer

- Fold In Ergonomic Contoured Armrest

- Control Interlock System, when operator leaves seat or armrest raised: Hydraulic System Disables, Hydrostatic Transmission Disables, Parking

- Brake Engages

- ROPS Cab, Tilt Up

- FOPS, Level I

- Top and Rear Windows

- Floor Mat

- Headliner

- Interior Rearview Mirror

- Horn

- Hand (Dial) Throttle, Electronic

- Seat Mounted Joystick Controls

- Cell Phone Storage Pocket

- Cup Holder

- 12-volt power port

- Foot Throttle

-

- Hydraulics

-

- Selectable control pattern – ISO or H

- Electro/hydraulic implement control

- Electro/hydraulic hydrostatic transmission control

- Speed sensor guarding

- Heavy duty flat faced quick disconnects with integrated pressure release lever

- Hydraulic oil level sight gauge

-

- Power Train

-

- Cat C2.8TA turbocharged, after-cooled diesel engine, meeting Tier 4 Final and Stage V Emission Standards: Glow plugs starting aid Liquid cooled, direct injection

- Extended life antifreeze (–37° C, –34° F)

- Air cleaner, dual element, radial seal

- Scheduled Oil Sampling (S·O·SSM) Valve, Hydraulic Oil

- Ecology drain – coolant

- Radiator coolant level sight gauge

- Radiator expansion bottle

- Filter, hydraulic supply, cartridge type

- Filter, hydraulic return, cartridge type

- Filter, canister type, engine oil

- Filter, canister type, fuel and water separator

- Radiator/hydraulic oil

- Cooler (side-by-side)

- Spring applied, hydraulically released, parking brakes

- Hydrostatic transmission

- Lockable fuel cap

- Hydraulic demand cooling fan

- Auto engine idle

-

- Undercarriage

-

- Torsion Suspension (4 independent torsion axles)

- Two speed travel

- Integrated tie downs on track frame (4)

-

- Frame

-

- Machine tie down points (9)

- Removable panels for machine frame cleanout

- Support, lift arm

- Steel rear and front bumpers, welded

- Fuel fill, machine right hand side

-

- Other

-

- Auxiliary Hydraulics, Continuous Flow

- Telematics, Product Link, Cellular

- Steel engine door with replaceable louvers

- Engine door – lockable

- Work tool attachment coupler

- Cat ToughGuardTM hose

Optional Equipment:

-

- Optional Equipment

-

- External Counterweights

- Beacon, LED

- Engine Block Heater – 120V

- Oil, Hydraulic, Cold Operation

- 4-point machine lifting eyes

- Paint, Custom

- Speed Sensitive Ride Control

- Bluetooth Key Security

- Attachment Hose Guide

- Corrosion Inhibitor Coating