434 Backhoe Loader

Backhoe Loaders

Center-Pivot Backhoe Loaders (7)

-

430 Backhoe Loader

-

450 Backhoe Loader

-

440 Backhoe Loader

-

420 XE Backhoe Loader

-

420 Backhoe Loader

-

416 Backhoe Loader

-

415 IL Industrial Loader

Side Shift Backhoe Loaders (3)

Overview

New Machines, Original DNA – The first Cat® backhoe loader hit the road in 1985. The machine was co-developed by a team of designers in Illinois, U.S. and a manufacturing team in Desford, UK. The machines are still designed by experts to meet the needs of today’s operators. Every model provides reliability, power and a top-quality operator environment to see you through the toughest projects. The latest backhoe loader range is crafted from 35 years of passion, expertise and experience.

- POWERFUL LOAD SENSING HYDRAULIC SYSTEM

- BACKHOE – BUILT FOR THE TASK

- POWER TRAIN – POWERFUL, PROVEN AND EFFICIENT

- LOADER PERFORMANCE – MAKING LIGHT WORK OF LIFTING AND LOADING

- THE CLASS LEADING OPERATOR ENVIRONMENT JUST GOT BETTER – SET YOUR MACHINE PERFORMANCE TO INCREASE PRODUCTIVITY AND EFFICIENCY

- ATTACHMENTS

- EASY TO OPERATE – EASY TO MAINTAIN

- YOUR MACHINE – YOUR SUPPORT

POWERFUL LOAD SENSING HYDRAULIC SYSTEM

FLOW-SHARING VALVES Actively manage the flow of oil between each function of the machine. When the operator demands multiple operations the machine responds, providing smooth, effortless operation.

BACKHOE – BUILT FOR THE TASK

HIGH-ROTATION LINKAGE The Cat backhoe linkage provides an industry-leading 205 degrees of bucket rotation. This design helps with material retention when truck loading and with vertical wall-trenching. Improved performance and efficiency are achieved by the ability to do more with less movement.

POWER TRAIN – POWERFUL, PROVEN AND EFFICIENT

C3.6 ENGINE The Cat C3.6 engine, which meets EU Stage V emission standards, reduces owning and operating costs while maintaining the same performance and power as the C4.4 engine. The aftertreatment is a compact, maintenance-free solution of DOC, SCR and DPF. The Cat C3.6 engine is a turbocharged in-line four-c...

LOADER PERFORMANCE – MAKING LIGHT WORK OF LIFTING AND LOADING

PARALLEL LIFT Parallel lift loader arms offer excellent forward visibility and self-leveling, ensuring excellent material retention throughout the lift and lower cycles.

THE CLASS LEADING OPERATOR ENVIRONMENT JUST GOT BETTER – SET YOUR MACHINE PERFORMANCE TO INCREASE PRODUCTIVITY AND EFFICIENCY

LCD OPERATOR DISPLAY The LCD operator display comes standard as a softkey display or can be upgraded to touchscreen. Through the interactive display you can get updates on machine diagnostics and upcoming service intervals, as well as being able to configure various performance parameters dependent on configuration. Thi...

ATTACHMENTS

A WIDE RANGE OF CAT ATTACHMENTS ARE AVAILABLE TO MEET THE NEEDS OF YOUR JOB SITE APPLICATIONS. Our attachments are engineered, balanced and tested to each Cat backhoe loader model, promising to minimize stress and optimize performance.

EASY TO OPERATE – EASY TO MAINTAIN

DAILY SERVICE POINTS Caterpillar understands that the easier a task is the more likely it is to be done. We have ensured that servicing the Cat backhoe loader is as simple as it can be. All daily fluid check points and are easy to access from a large service platform.

YOUR MACHINE – YOUR SUPPORT

MACHINE SELECTION Your dealer can help you with your machine purchase decision, based on your requirements and help keep operating costs to a minimum. Is the machine you have in mind exactly the best for your job, or could there be a more suitable solution?

POWERFUL LOAD SENSING HYDRAULIC SYSTEM

FLOW-SHARING VALVES Actively manage the flow of oil between each function of the machine. When the operator demands multiple operations the machine responds, providing smooth, effortless operation.

VARIABLE DISPLACEMENT PISTON PUMP A high capacity variable displacement piston pump allows for perfect matching of power and operator demand, providing power when it is needed whilst contributing to great fuel economy.

MORE LIFTING PERFORMANCE The option of a larger boom cylinder is available on the 434 giving increased lifting performance against the standard boom cylinder. This option is available with either mechanical or pilot controls.

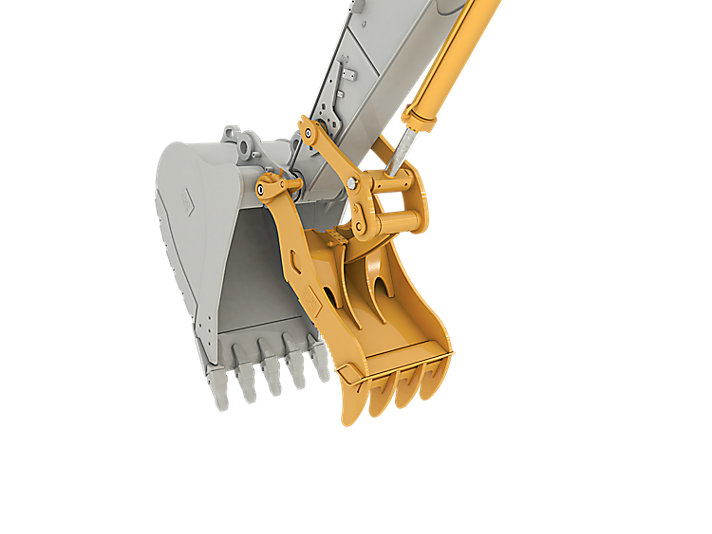

BACKHOE – BUILT FOR THE TASK

HIGH-ROTATION LINKAGE The Cat backhoe linkage provides an industry-leading 205 degrees of bucket rotation. This design helps with material retention when truck loading and with vertical wall-trenching. Improved performance and efficiency are achieved by the ability to do more with less movement.

EXCAVATOR-STYLE BOOM Whether close-up truck loading or digging over obstacles, the iconic excavator-style boom tackles the toughest jobs with ease. Combine this versatility with powerful breakout forces, controllability, a powerful hydraulic system and the 434 is capable of high levels of productivity with minimum effort. The boom is a narrow design, ensuring maximum visibility to the attachment and ground.

CAT CUSHION SWING The standard Cat Cushion Swing System smooths the backhoe swing function when returning to the trench. Operators will immediately appreciate being able to line up the bucket edge on the trench wall faster and with more control.

SIDE SHIFT FRAME The Side Shift Frame has exterior lock clamps, with no disassembly needed when servicing. The frame is a solid design with E-Coat protection preventing material build up in the frame, reducing the risk of rust and increasing the life of the frame.

EXTENDIBLE STICK The extendible stick comes as an option for applications where more versatility is needed. Increasing dig depth and reach capability by 922 mm reduces the amount of machine repositioning and therefore reducing site damage and increasing productivity. A sliding inner section design helps to ensure the wear pads remain as dirt free as possible, prolonging adjustment and replacement intervals. Auxiliary lines, for operating hydraulic attachments, have been routed so that they are protected from damage when working in the narrowest of trenches.

POWERED SIDE SHIFT (OPTIONAL) Available as an option either from the factory or as a dealer fitted kit, the powered side shift solution provides a hydraulic service to allow the operator to easily position the backhoe across the full width of the Side Shift Frame. Ideal for use in areas with minimal space and utility applications such as gas, electrical, and telecoms.

POWER TRAIN – POWERFUL, PROVEN AND EFFICIENT

C3.6 ENGINE The Cat C3.6 engine, which meets EU Stage V emission standards, reduces owning and operating costs while maintaining the same performance and power as the C4.4 engine. The aftertreatment is a compact, maintenance-free solution of DOC, SCR and DPF. The Cat C3.6 engine is a turbocharged in-line four-cylinder, four-stroke cycle with direct injection diesel engine. Cold starting capability down to –25˚C comes as standard with a cold starting package option allowing the machine to start down to –47˚C. This engine has a 12 volt starting motor with a 750 CCA maintenance-free battery. This engine gives up to 10% fuel savings, based upon application and machine setting, compared to the C4.4 engine.

POWER MANAGEMENT MODES Three power management modes are available: Eco (Only when equipped with powershift/autoshift transmission), Standard and Standard Plus. Depending upon application or performance needs, the operator can select the mode that gives optimum results. Eco mode limits both pump flow and engine speed giving higher fuel saving benefits whereas Standard Plus gives maximum pump flow and engine speed, providing increased power and performance where needed.

TRANSMISSIONS The 4-speed manual transmission is standard on the 434. A 4-speed powershift transmission is available as an optional upgrade. Improved operator comfort and reduced fatigue is achieved by operation through the directional control lever, rather than floor mounted lever, to shift gears. For those operators doing a lot of roading the autoshift transmission with lock-up torque convertor is an ideal option as it can give up to 15% fuel efficiency savings on the road whilst maintaining travel speed in hilly environments.

AXLES AND DIFFERENTIAL LOCK Heavy duty axles and a 100% locking rear differential come as standard on Cat backhoe loaders. The axles provide high durability whilst providing superb traction on uneven surfaces. No daily greasing is required on the front axle helping to save both time and money, keeping owning and operating costs as low as possible. The Diff-lock improves performance by giving maximum traction in all conditions.

EQUAL SIZED TIRES With four equal sized tires, this machine is capable of increased lifting performance. Better flotation makes an EST ideal for applications with poor ground conditions. The EST machines also offer all wheel steering to improve maneuverability around the job site.

LOADER PERFORMANCE – MAKING LIGHT WORK OF LIFTING AND LOADING

PARALLEL LIFT Parallel lift loader arms offer excellent forward visibility and self-leveling, ensuring excellent material retention throughout the lift and lower cycles.

RIDE CONTROL This option offers loader suspension to improve operator comfort and productivity. When moving around the job site or transporting the machine on the road, ride control provides extra stability which creates an easier ride for the operator and helps material retention to improve operator efficiency.

RETURN TO DIG Return to Dig allows the operator to return the bucket to a preset level, this is great for applications with repetitive work cycles especially when working with forks. When not required, for instance when grading with the loader bucket, Return to Dig can be turned off within the display screen.

IT QUICK COUPLER This option is available from the factory or as a kit, providing the extra versatility needed when working in multiple applications. This coupler allows a quick and safe change between multiple attachments from the inside of the cab.

THE CLASS LEADING OPERATOR ENVIRONMENT JUST GOT BETTER – SET YOUR MACHINE PERFORMANCE TO INCREASE PRODUCTIVITY AND EFFICIENCY

LCD OPERATOR DISPLAY The LCD operator display comes standard as a softkey display or can be upgraded to touchscreen. Through the interactive display you can get updates on machine diagnostics and upcoming service intervals, as well as being able to configure various performance parameters dependent on configuration. This helps to match machine performance to operator preference further increasing productivity and efficiency. Optional machine security system is embedded into the display screen helping to keep your Cat backhoe loader secure.

OPERATOR COMFORT To reduce operator fatigue and increase efficiency, the air suspension seat comes as standard with switches and controls being ergonomically located within reach of the operator. Diff-Lock button, Transmission kickdown and auxiliary controls are all located on the loader control joystick giving power and control at the operator’s fingertips. Great visibility allows the operator to get the job done in a safe and efficient manner.

HOE PILOT CONTROLS Hoe Pilot controls are available as an option on the 434. These are mounted on fully adjustable pods that the operator can position to their preference. These controls increase operator comfort by having them located in the most ergonomic position as well as being easier and smoother to operate than the standard mechanical controls. The loader control will remain mechanical.

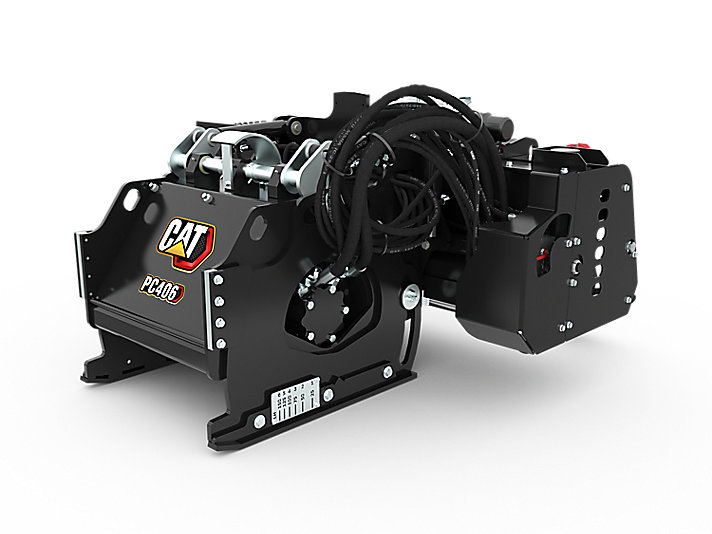

ATTACHMENTS

A WIDE RANGE OF CAT ATTACHMENTS ARE AVAILABLE TO MEET THE NEEDS OF YOUR JOB SITE APPLICATIONS. Our attachments are engineered, balanced and tested to each Cat backhoe loader model, promising to minimize stress and optimize performance.

LOADER BUCKETS General Purpose loader buckets are available as well as the hydraulically operated Multi-Purpose bucket.

OTHER AVAILABLE LOADER TOOLS INCLUDE:

OTHER AVAILABLE LOADER TOOLS INCLUDE:

- BROOMS

- MATERIAL HANDLING ARMS

- TRUSS BOOMS

- FORKS

- BLADES

EXCAVATING BUCKETS Cat Attachments provide a range of buckets in various sizes. It is easy to find the correct bucket for the application with a range including:

OTHER AVAILABLE BACKHOE TOOLS INCLUDE:

- STANDARD DUTY

- HEAVY DUTY

- HIGH CAPACITY HD

- DITCH CLEANING

- CRIBBING

- GRADING

OTHER AVAILABLE BACKHOE TOOLS INCLUDE:

- COLD PLANERS

- HAMMERS

- AUGERS

- VIBRATORY COMPACTION PLATES

- RIPPER

BACKHOE QUICK COUPLER Manual or hydraulic backhoe couplers make rear tool exchange quick, easy and safe. Cat dual-lock couplers have a self-adjusting wedge design to ensure a tight fit. They also feature a safety lock which automatically engages.

EASY TO OPERATE – EASY TO MAINTAIN

DAILY SERVICE POINTS Caterpillar understands that the easier a task is the more likely it is to be done. We have ensured that servicing the Cat backhoe loader is as simple as it can be. All daily fluid check points and are easy to access from a large service platform.

HINGED COOLING PACK The hood opens to reveal the engine and a unique Cat designed hinged cooling pack. The air conditioning pack lifts up and the radiator tilts forward with no tooling required, giving easy access for debris removal whether you are in the workshop or on a job site, keeping optimal cooling performance.

WEAR PAD ADJUSTMENTS The Extendible Stick (E-Stick) is designed to be self-lubricating, to minimize the need for operator interaction. The stabilizers and E-Stick all have easily adjustable wear pads that require no disassembly. When wear pad adjustments are necessary, the adjustment bolts are easy to access, taking minutes to complete.

CAT FILTERS All Cat filters are vertically mounted for spill free servicing and reduced oil contamination. These low micron filters remove microscopic particles from the oil, keeping the engine, transmission and hydraulic system running smoothly for years.

A-PIN GREASING A-Pin grease point has been relocated to give ground level access without needing access to the engine bay, reducing time spent maintaining the machine.

BATTERY/STORAGE BOX The batteries and battery disconnect switch are conveniently located in the external right hand side lockable storage box for easy access. The box also leaves sufficient space to be able to store grease gun, spanner, etc.

YOUR MACHINE – YOUR SUPPORT

MACHINE SELECTION Your dealer can help you with your machine purchase decision, based on your requirements and help keep operating costs to a minimum. Is the machine you have in mind exactly the best for your job, or could there be a more suitable solution?

CUSTOMER VALUE AGREEMENTS (CVA'S) Your Cat dealer can offer a comprehensive range of CVA’s which can be individually tailored to suit your requirements. Dealers can offer a range of options from a full preventative maintenance with S·O·SSM package to a parts only CVA. Protect your valuable investment and know exactly what your monthly payments will be to help you run your business.

EQUIPMENT PROTECTION PLAN (EPP) You count on your Cat machines to get the job done, day in and day out. Choose a protection plan that’s just as dependable and long-lasting. EPP offers the only coverage designed specifically for new Cat equipment – giving you the highest level of repair cost protection available. Talk to your dealer today to find out what EPP solution is the best for you!

FINANCE Have you explored the range of options available from your dealer to finance your machine? They can offer a selection of attractive packages tailored to suit your every requirement.

TRAINING AND SUPPORT Speak to your dealer about any additional support you may need. They can give you the latest in operating techniques to minimize wear and tear, maximize productivity, lower owning and operating costs and help you make the most of the fantastic features offered on the Cat backhoe loaders.

Engine

- Power - Net

- 92hp

- Power

- 74.4 kW

Engine - EU Stage V (Standard)

- Net Torque - SAE J1349

- 322lb/ft

- Displacement

- 220in³

- Note (2)

- No derating required up to 3048 m altitude. Auto derate protects hydraulic and transmission systems.

- Bore

- 3.86in

- Note (1)

- Net power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, muffler and alternator.

- Torque Rise (net)

- 48% @ 1,500 rpm

- Stroke

- 4.72in

- Emissions

- Meets EU Stage V emission standards.

- Engine

- C3.6 74.4 kW Electronic Turbo Intercooled

- Ratings at 2,200 rpm - Engine Power ISO 14396:2002

- 74 kW/101 hp

- Net Power Rating @ 2,200 rpm - SAE J1349:2011

- 68 kW/92 hp

- Note (3)

- Advertised power is tested per the specified standard in effect at the time of manufacture.

- Ratings at 2,200 rpm - Gross Power SAE J1995:2014

- 76 kW/103 hp

- Net Power Rating @ 2,200 rpm - ISO 9249:2007

- 68 kW/92 hp

Weights

- Operating Weight - Nominal

- 20216lb

- Operating Weight - Maximum

- 25353lb

- Ride Control

- 33lb

- Minimum Counterweight Recommendations - Extendible Stick: Loader Bucket - GP

- 0lb

- Minimum Counterweight Recommendations - Standard Stick: Loader Bucket - GP

- 0lb

- Air Conditioning

- 71lb

- Extendible Stick - Excludes Front Counterweight

- 448lb

- Counterweights - Base

- 254lb

- Counterweights - Maximum

- 254lb

- Minimum Counterweight Recommendations - Extendible Stick: Loader Bucket - MP

- 0lb

- Operating Weight

- 20216lb

- MP Bucket (1.15 m3/1.50 yd3) - Without Fold-Over Forks

- 1711lb

- Operating Weight - Maximum - ROPS Capacity

- 25353lb

- Auto-Shift Transmission

- 240lb

- Minimum Counterweight Recommendations - Standard Stick: Loader Bucket - MP

- 0lb

- MP Bucket (1.15 m3/1.50 yd3) - With Fold-Over Forks

- 2150lb

- Total Gross Weight Not to Exceed

- 25353lb

- Note

- Machine Configuration – HRC 74.5 kW engine; standard stick hoe; standard cab with A/C; AWD standard shift transmission; 1.15 m3 MP loader bucket; 600 mm standard duty hoe bucket; 440/80R24 tires; no counterweight; 80 kg operator; full fuel tank.

- Cab - ROPS/FOPS

- Standard

Backhoe Digging Depth

- Dig Depth

- 4827 mm/5748 mm (E-Stick)

Loader Performance

- Breakout Force

- 13646lbf

Operator Station

- Controls

- Mechanical Loader; Mechanical Hoe (Pilot Hoe Optional)

Transmission

- Note

- Travel speeds of backhoe loader at full throttle, when equipped with 440/80-28 rear tires.

Transmission - Standard Shift Transmission (Standard)

- Forward - 4th

- 24.9mile/h

- Forward - 2nd

- 5.6mile/h

- Reverse - 1st

- 3.7mile/h

- Reverse - 3rd

- 13mile/h

- Reverse - 2nd

- 5.6mile/h

- Forward - 3rd

- 13mile/h

- Reverse - 4th

- 24.9mile/h

- Forward - 1st

- 3.7mile/h

Transmission - Powershift Transmission (Optional)

- Forward - 2nd

- 6.2mile/h

- Reverse - 3rd

- 16.8mile/h

- Forward - 4th

- 24.9mile/h

- Reverse - 2nd

- 7.5mile/h

- Reverse - 1st

- 3.7mile/h

- Forward - 3rd

- 12.4mile/h

- Forward - 1st

- 3.7mile/h

Transmission - Auto-Shift Transmission (Optional)

- Forward - 3rd

- 7.5mile/h

- Forward - 1st

- 3.7mile/h

- Forward - 2nd

- 6.2mile/h

- Forward - 6th

- 24.9mile/h

- Reverse - 1st

- 3.7mile/h

- Forward - 5th

- 16.8mile/h

- Forward - 4th

- 12.4mile/h

- Reverse - 3rd

- 16.8mile/h

- Reverse - 2nd

- 7.5mile/h

Transmission - Auto-Shift Transmission with Lock-Up Torque Converter (Optional)

- Forward - 6th

- 24.9mile/h

- Forward - 4th

- 12.4mile/h

- Reverse - 3rd

- 16.8mile/h

- Reverse - 1st

- 3.7mile/h

- Forward - 3rd

- 7.5mile/h

- Forward - 5th

- 16.8mile/h

- Forward - 1st

- 3.7mile/h

- Forward - 2nd

- 6.2mile/h

- Reverse - 2nd

- 7.5mile/h

Axle Ratings

- Rear Axle - Dynamic

- 20252lb

- Rear Axle - Static

- 50627lb

- Front Axle - Dynamic

- 20252lb

- Front Axle - Static

- 50627lb

Hydraulic System

- System Pressure - Loader

- 3626psi

- System Pressure - Backhoe

- 3626psi

- Pump Capacity @ 2,200 rpm

- 42.3gal/min

- Type

- Closed Center

- Pump Type

- Variable-Flow, Axial Piston

Steering

- AWD Cylinder, One (1) Double Acting - Rod Diameter

- 1.7in

- AWD Cylinder, One (1) Double Acting - Stroke

- 4.6in

- AWD Cylinder, One (1) Double Acting - Bore

- 3.3in

- Turning Circle (28" Tires) - AWD (inner wheel not braked) - Outside Front Wheels

- 32.15ft

- Turning Circle (28" Tires) - AWD (inner wheel not braked) - Outside Widest Loader Bucket

- 41.34ft

- Type

- Front Wheel

- Power Steering

- Hydrostatic

Service Refill Capacities

- Rear Axle - Planetaries

- 0.4gal (US)

- Cooling System - A/C

- 4.6gal (US)

- Engine Oil - With Filter

- 2.4gal (US)

- Diesel Exhaust Fluid

- 5gal (US)

- Hydraulic Tank

- 11.1gal (US)

- Rear Axle

- 4.2gal (US)

- Fuel Tank

- 42.3gal (US)

- Hydraulic System

- 25.1gal (US)

- Front Axle - Planetaries

- 0.4gal (US)

- Front Axle

- 3.7gal (US)

Service Refills Capacities

- Transmission (Standard Shift)

- 4.8gal (US)

- Transmission (Powershift/Autoshift)

- 5gal (US)

Standard/Optional Features

Standard Equipment:

-

- Cab Rops And Fops

-

- Cab, Standard

-

- Tires/steering/brakes

-

- All Wheel Drive

- All Wheel Steer

- 100% Differential Lock

- Hydraulic Boosted Brakes

- Tires 24 inch

-

- Engine/transmission

-

- Engine, C3.6 74.4 kW

- Battery, 750 CCA, Standard

- Hinged Radiator Pack

- Standard Mode

- Transmission Neutralizer

- Transmission, Four Speed Standard Shift

-

- Controls

-

- Controls, Mechanical Levers

- Power Steering, Hydrostatic

-

- Electrical

-

- Display Screen, Soft Key

- Product Link Cellular

- Reversing Alarm

- Stabilizer Alarm

-

- Hydraulics

-

- Variable Displacement Piston Pump

- Side Shift Lock

- Hydraulic Oil Cooler

- Loader Kickout, Float

- Loader Kickout, Return to Dig

-

- Booms, Sticks And Linkages

-

- Stick Standard, 4.3 m

- Transport Lock, Swing

- Transport Lock, Boom

-

- Other Attachments

-

- External Tool Box

- Transport Tie Downs

Optional Equipment:

-

- Cab Rops And Fops

-

- Cab, Deluxe

-

- Tires/steering/brakes

-

- Tires 28 inch

-

- Engine/transmission

-

- Battery, 750 CCA, Heavy Duty

- Auto Idle

- Eco Mode

- Standard + Mode

- Engine Block Heater

- Transmission, Four Speed Powershift

- Transmission, Six Speed Autoshift

- Transmission, Six Speed Autoshift with Lock-Up Torque Converter

-

- Controls

-

- Controls, Pilot Hoe Joysticks

- Pattern Selector (ISO/SAE)

-

- Electrical

-

- Display Screen, Touchscreen

- Product Link, Dual Mode (cellular and satellite)

- Beacon, Rotating

- Beacon, Strobe

-

- Hydraulics

-

- Hydraulic Quick Disconnects

- Hydraulic Lines, One Way

- Hydraulic Lines, Two Way

- Powered Side Shift

- Ride Control

- Continuous Flow

- Programmable Auxiliary Flow

-

- Booms, Sticks And Linkages

-

- Stick Extending, 4.3 m

- Hoe Quick Coupler, Mechanical

- Hoe Quick Coupler, Hydraulic

- Loader Quick Coupler, Hydraulic

-

- Other Attachments

-

- Counterweight, 115 kg

- Counterweight, 240 kg

- Counterweight, 460 kg

- Front Fenders

- Street Pads, Stabilizers

432 Backhoe Loader

432 Backhoe Loader  428 Backhoe Loader

428 Backhoe Loader