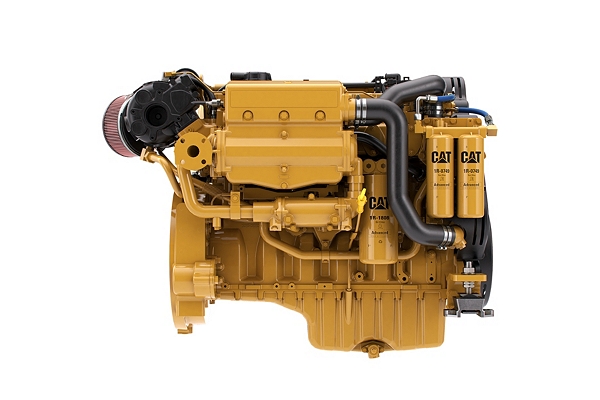

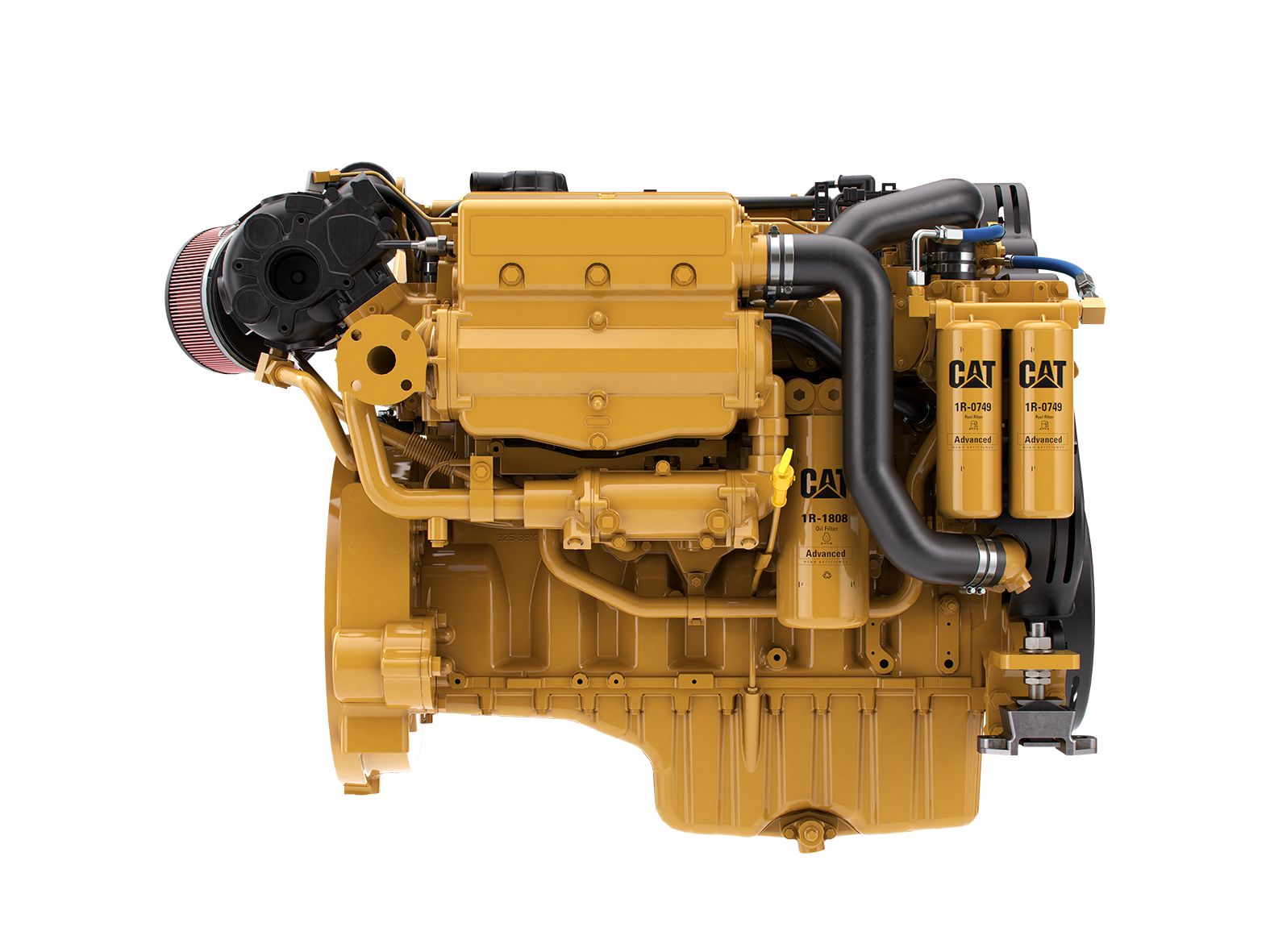

C9.3 Commercial Propulsion Engine

-

C280-8 Marine Propulsion Engine (U.S. EPA Tier 4)

-

C280-12 Propulsion Engine

-

C280-12 Marine Propulsion Engine (EPA Tier 4)

-

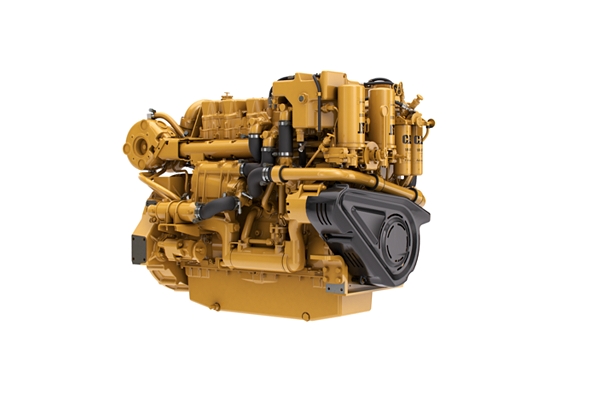

3508C Propulsion Engine

-

3512C Tier 3 Marine Propulsion Engine

-

3516C Propulsion Engine (Tier 3)

-

Cat C18 ACERT Propulsion Engine (IMO II)

-

C280-16 Commercial Marine Propulsion Engine

-

C280-6 Propulsion Engine

-

Cat C280-8 Propulsion Engine

-

3516E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3512E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3516C Marine Propulsion Engine

-

Cat C32 Propulsion Engine (US EPA Tier 4 / IMO III)

-

3512C Propulsion Engine (IMO II)

-

Cat C32 ACERT Marine Propulsion Engine (EPA Tier 3)

-

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

-

C9.3 Commercial Propulsion Engine

-

Cat C18 ACERT Propulsion Engine (Tier 3)

-

Cat C32 Propulsion Engine (IMO II)

-

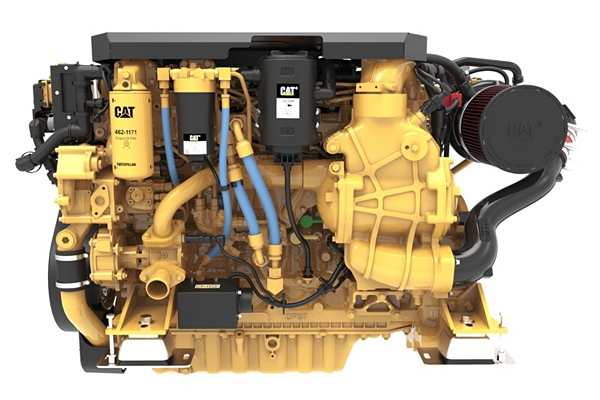

C7.1 Marine Propulsion Engine (U.S. EPA Tier 3 / IMO II)

Overview

The C9.3 ACERT propulsion engine has a B rating of 375 bhp (280 bkW) at 1800 rpm, a C rating of 416 bhp (310 bkW) at 2100 rpm, and a D rating of 476 bhp (355 bkW) at 2300 rpm. The C9.3 propulsion, auxiliary, and generator set engines have a common rail fuel system for optimal combustion and lower emissions. Cooling system options for the propulsion and auxiliary engines include heat exchanger with sea water aftercooling, and keel with combined circuit or separate circuit aftercooling. The genset packages are available with heat exchanger, keel, or radiator cooling. These products are EPA Tier 3 and IMO II certified. In addition the propulsionengine ratings are EU Stage IIIA certified and auxiliary and gen sets are also CCNR Stage II certified.

- Electronic control system provides industry-leading torque and throttle response at low speeds, while maintaining fuel efficiency at high speeds

- Common rail fuel system enables optimum combustion and low emissions

- RH and LH locations service options for fuel and oil filters, as well as dipstick location for easily accessible service

- Electronic control system provides industry-leading torque and throttle response at low speeds, while maintaining fuel efficiency at high speeds

- Common rail fuel system enables optimum combustion and low emissions

- RH and LH locations service options for fuel and oil filters, as well as dipstick location for easily accessible service

- Compatible with Cat® displays

- Available remote-mounted display panel with start, stop, and engine diagnostics

- 12V or 24V electrical system

- Certified by all marine classification societies

Power Rating

- Power Range

- 375-476 bhp (280-355 bkW)

- Power Range

- 375-476 bhp (280-355 bkW)

Engine Specifications

- Speed Range

- 1800-2300 rpm

- Emissions

- EPA Tier 3 Commercial, IMO II, EU IW

- Aspiration

- TA

- Bore

- 4.53in

- Stroke

- 5.87in

- Displacement

- 568in3

- Speed Range

- 1800, 2100, 2300 rpm

- Configuration

- In-line 6, 4-Stroke-Cycle Diesel

- Rotation from Flywheel End

- Counterclockwise

- Emissions

- IMO II, U.S. EPA Tier 3, China Stage II

- Aspiration

- Turbocharged-aftercooled

- Bore

- 4.5in

- Stroke

- 5.8in

- Displacement

- 567.5in³

- Rated Engine Speed

- 1800, 2100, 2300 rpm

- Governor

- Electronic

- Refill Capacity

- Lube Oil System w/oil filter change: 24.5 L (6.5 gal)

- Oil Change Interval

- 500 hrs

- Flywheel Housing

- SAE No. 1 (113 teeth)

- Cooling

- Heat exchanger and separate or combined keel cooled options

Dimensions & Weights

- Engine Dry Weight (approx.)

- 945-1122 kg (2083-2474 lbs)

- Length of Engine

- 57.2in

- Width of Engine

- 38.5in

- Height

- 43in

- Engine Dry Weight - Approximate

- 945-1122 kg (2083-2474 lbs)

- Length - Engine

- 57.2in

- Width - Engine

- 38.5in

Standard/Optional Features

Standard Equipment:

-

- Standard Equipment

-

- Water-cooled turbocharger and exhaust manifold

- Electronic control system

- Thermostats and housing

- Gear-driven Sea water pump (self-priming)

- Common rail fuel system

- Shell and tube jacket water heat exchanger

- Corrosion-resistant Sea water aftercooler

- Engine oil cooler

- Vibration damper and guard

- Primary fuel filters

Optional Equipment:

-

- Optional Attachments

-

- Alternators - 24V 70 or 105 amp, 12V 110 amp

- Closed crankcase ventilation

- Transmission gear oil cooler (engine mounted for HEX)

- Additional engine and transmission sensor packages

- Instrument panels

- Electric starting motors - 12V or 24V

- Air starting motor

- Dual electric starting motors or combined electric/air

- Electric fuel priming pump

- Fuel cooler

- PTO Drives - V-belt pulley stack, stub shaft

- Duplex fuel and oil filters

- Double wall fuel rail