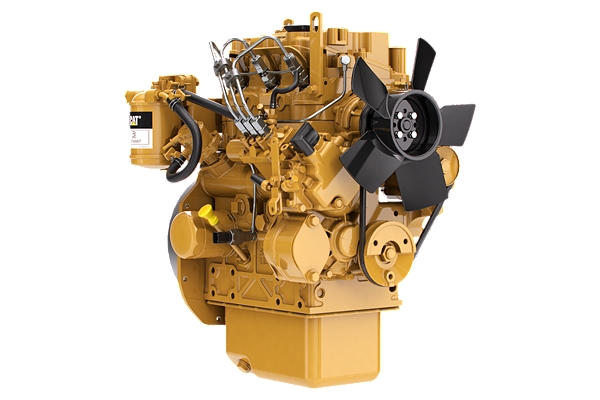

Cat® C2.2 Diesel Engine

Industrial

Industrial (71)

-

Cat® C9 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

Cat® C2.2 Diesel Engine

-

Cat?� 3512 Fire Pump

-

Cat?� 3516 Fire Pump

-

Cat?� 3406C Fire Pump Engine

-

Cat?� 3508 Fire Pump

-

Cat?� C18 Diesel Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat?� C18 Industrial Power Unit

-

Cat?� C15 Industrial Power Unit

-

Cat?� C13 Industrial Power Unit

-

Cat?� C11 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C32 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C18 Industrial Power Unit (<560 kW)

-

Cat?� C15 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit HRC

-

Cat?� C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� 3616 Industrial Diesel Engine

-

Cat?� 3612 Industrial Diesel Engine

-

Cat?� 3608 Industrial Diesel Engine

-

Cat?� 3606 Industrial Diesel Engine

-

Cat?� 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat?� 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat?� 3512B Industrial Diesel Engine

-

Cat?� 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat?� 3508 Diesel Engine

-

Cat?� C32

-

Cat?� C27 Industrial Diesel Engine

-

Cat?� C18 Industrial Diesel Engine

-

Cat?� C15 Industrial Diesel Engine

-

Cat?� 3406C Diesel Engine

-

Cat?� C13 Industrial Diesel Engine

-

Cat?� C11 Industrial Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7 Industrial Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?�3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat?� C3.6 Industrial Diesel Engine

-

Cat?� C2.8 Industrial Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C0.7 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat?� 3516E Diesel Engine

-

Cat?� C32 Diesel Engine

-

Cat?� C32B HRC Diesel Engine

-

Cat?� C27 Diesel Engine

-

Cat?� C9.3B Diesel Engine

-

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C3.6 Diesel Engine

-

Cat® C2.8 Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C0.5 Diesel Engine

Overview

The new electronic Cat® C2.2 Industrial Diesel Engines, with common rail fuel system, deliver impressive performance throughout a wide speed range with exceptional power density. Ultracompact package size and extensive options make them ideal for agriculture, aerial lifts, compressors, construction, general industrial, irrigation equipment, material handling, mobile earthmoving equipment, mobile light towers, turf and landscaping, underground mining equipment, and welders.

- Reliable, Quiet and Durable Power

- High Performance

- Fuel Efficiency

- Broad Application Range

- Package Size

- World-class Product Support Offered Through Global Cat Dealer Network

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Substantial torque rise delivers impressive performance throughout a wide speed range while maintaining low operating costs.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Broad Application Range

Industry leading ratings and options for compact construction equipment, material handling, and other industrial applications. The engine is designed to require no special training or operation, which makes it particularly suitable for machines that are used in rental fleets.

Package Size

Ultra-compact package size and high power density ensures ease of installation. It also allows machine manufacturers to develop smaller machines, with low weight for transport, tight turning circles for productivity, and good sight lines for safety.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including S•O•S℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program<...

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Substantial torque rise delivers impressive performance throughout a wide speed range while maintaining low operating costs.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Broad Application Range

Industry leading ratings and options for compact construction equipment, material handling, and other industrial applications. The engine is designed to require no special training or operation, which makes it particularly suitable for machines that are used in rental fleets.

Package Size

Ultra-compact package size and high power density ensures ease of installation. It also allows machine manufacturers to develop smaller machines, with low weight for transport, tight turning circles for productivity, and good sight lines for safety.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including S•O•S℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

General

- Engine Configuration

- In-Line 4, 4-Stroke-Cycle Diesel

- Cooling System Capacity

- 4.3 L (4.5 qt)

- Lube System (refill)

- 9.3 L (9.8 qt)

- Bore

- 3.3in

- Stroke

- 3.9in

- Displacement

- 135in³

- Aspiration

- Turbocharged (T)

- Compression Ratio

- 18.0:1

- Combustion System

- Direct Injection

- Rotation from Flywheel End

- Counterclockwise

- Engine Configuration

- In-Line 4

- Bore

- 84 mm (3.3 in)

- Stroke

- 100 mm (3.9 in)

- Displacement

- 2.2 L (135 in³)

- Cooling System - Capacity

- 4.3 L (4.5 qt)

- Lube System - Refill

- 9.3 L (9.8 qt)

- Aftertreatment

- DOC

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 764 mm (30.07 in)

- Width

- 545 mm (21.5 in)

- Height

- 736 mm (28.9 in)

- Weight - Net Dry (Basic Operating Engine Without Optional Attachments)

- 230 kg (507 lbs)

Aftertreatment Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 408.4 mm (16.07 in)

- Weight

- 5.8 kg (12.79 lb)

- Diameter

- 155 mm (6.1 in)

- Length, including bolt heads

- 408.4 mm (16.1 in)

- Diameter, to cover bolts

- 167 mm (6.6 in)

Power Rating

- Minimum Power

- 48.8HP

- Maximum Power

- 48hp

- Rated Speed

- 2800 rpm

- Maximum Torque

- 122lb-ft @ 1800 rpm

Emission Standards

- Emissions

- U.S. EPA & CARB Tier 4 Final

Engine Dimensions - Approximate

- Height

- 720 mm (28.3 in)

- Length

- 723 mm (28.4 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 230 kg (507 lbs)

- Width

- 545 mm (21.4 in)

- Length

- 30.1in

- Width

- 21.4in

- Height

- 29in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 507lb

Aftertreatment Dimensions - Approximate

- Diameter

- 155 mm (6.1 in)

- Length

- 408.4 mm (16.0 in)

- Weight

- 5.8 kg (12.8 lb)

Aftertreatment Dimensions

- Length

- 16in

- Weight

- 12.5lb

Aftertreatment Dimensions*

- Diameter

- 6.1in

Standard/Optional Features

Standard Equipment:

-

- Control System

-

- Alternator 12 volt 85 amp

- Starter motor 12 volt

- Glow plug starting aid, delivers heat directly to cylinder for best starting performance in cold weather

- Electronic control unit - chassis mounted

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Wiring harness connectors and sensors are waterproof and designed to withstand harsh off-highway environments

-

- Flywheels And Flywheel Housing

-

- SAE No. 4 standard flywheel housing

- Choice of flywheel weight and bolting pattern to accommodate a range of industry-standard hydraulic pumps and transmissions

-

- Fuel System

-

- 2000 bar high-pressure common rail system

- Proprietary fuel filters to ensure engine protection through correct service procedures, along with water-in-fuel detection, ensures maximum machine up-time for the operator

-

- Lube System

-

- Alternative oil fillers

- Spin-on lube oil filter

-

- Power Take Off (pto)

-

- SAE A PTO drive

-

- General

-

- Cast iron engine block

- Cast iron exhaust manifold

- Gradeability 35° continuous

- Paint: Cat yellow

-

- U.s. Epa Tier 4 Final, Eu Stage Iiib Aftertreatment/clean Emissions Control Equipment

-

- Diesel Oxidation Catalyst (DOC)

Optional Equipment: